There are previous threads but thought I'd post my method, which is pretty easy.

Had to replace the 35 year old fuel hoses, which meant pulling the tank. Here's the low corner with the sending unit and before de-fueling the fuel level was at about the bottom of the sending unit housing. The floor of the tank was about like soft asphalt and the walls were fairly hardened with a bit of stickiness. A paint scraper will not work.

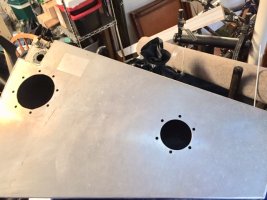

Here's the uphill baffle corner:

Capped all of the outlets, poured in a gallon of acetone, swished it around to wet all the surfaces, and let it sit outside in the yard for about two days. Occasionally I'd swish it again in that period.

Drained the acetone thru the fill port back into the gallon can for haz-mat disposal and most of the gunk came out like gritty brown paint. At this point the inside of the tank still has stuff clinging to the surfaces and touching it is pretty oily. Plus from past experience, the acetone dries fast and leaves a hard residue. This is the point to mix up two buckets of hot water with a half bottle of Pine-Sol in each and pour one in. Cap the fill tube and tank inspection port and swish it again. Let it sit a while.

Put on a pair of long sleeve gloves: https://www.harborfreight.com/oil-re...ves-99677.html

Open the inspection port and get to everything possible with a kitchen bottle brush and scotch-brite pads.

Dump it back into the bucket.

Rinse.

Put in the second bucket of Pine-Sol, swish it and let it sit for another day.

Dump the Pine-Sol, rinse till the water is clear, and let it dry. Getting in there with my phone camera, you can see that even where I missed isn't too bad and the baffled area which I could not get to should look the same.

btw -

It turned out the tank needed to come out anyway, as there were two pin-hole leaks at chafe points and each were where previous repairs had been in touch with the fiberglass hull. I'll be re-installing the tank on rubber shower pan liner.

(I'd already scotch brited the brown tell-tale stain off before taking the photo.)

Had to replace the 35 year old fuel hoses, which meant pulling the tank. Here's the low corner with the sending unit and before de-fueling the fuel level was at about the bottom of the sending unit housing. The floor of the tank was about like soft asphalt and the walls were fairly hardened with a bit of stickiness. A paint scraper will not work.

Here's the uphill baffle corner:

Capped all of the outlets, poured in a gallon of acetone, swished it around to wet all the surfaces, and let it sit outside in the yard for about two days. Occasionally I'd swish it again in that period.

Drained the acetone thru the fill port back into the gallon can for haz-mat disposal and most of the gunk came out like gritty brown paint. At this point the inside of the tank still has stuff clinging to the surfaces and touching it is pretty oily. Plus from past experience, the acetone dries fast and leaves a hard residue. This is the point to mix up two buckets of hot water with a half bottle of Pine-Sol in each and pour one in. Cap the fill tube and tank inspection port and swish it again. Let it sit a while.

Put on a pair of long sleeve gloves: https://www.harborfreight.com/oil-re...ves-99677.html

Open the inspection port and get to everything possible with a kitchen bottle brush and scotch-brite pads.

Dump it back into the bucket.

Rinse.

Put in the second bucket of Pine-Sol, swish it and let it sit for another day.

Dump the Pine-Sol, rinse till the water is clear, and let it dry. Getting in there with my phone camera, you can see that even where I missed isn't too bad and the baffled area which I could not get to should look the same.

btw -

It turned out the tank needed to come out anyway, as there were two pin-hole leaks at chafe points and each were where previous repairs had been in touch with the fiberglass hull. I'll be re-installing the tank on rubber shower pan liner.

(I'd already scotch brited the brown tell-tale stain off before taking the photo.)