ron7546

Member II

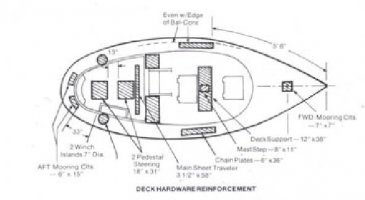

OK- the project is finally coming together.Started last fall gathering material for leading everything aft.BUT-new waterlift system,new AC wiring and etc. trumpted in.The mast plate is in ,the winches are installed with .187" s-s backer plates(which are hidden in the little compartments by the companionway on an E27). The holes are drilled for the organizers and rope clutches.Question being? ? ? I read a lot about removing core material and filling with Epoxy. I find on my 1976 E27 very little core material and about

1 1/4" of deck thickness.I wonder if it is necessary to remove and epoxy and if so do I drill a larger hole than necessary (to accomodate the mtg. hardware) to accomplish the task and redrill? ? To what extent do I go?

Ron

"Bluenote"

1 1/4" of deck thickness.I wonder if it is necessary to remove and epoxy and if so do I drill a larger hole than necessary (to accomodate the mtg. hardware) to accomplish the task and redrill? ? To what extent do I go?

Ron

"Bluenote"