I looked over my exhaust system today and to the best of my knowledge, I have no water lift muffler of any kind.

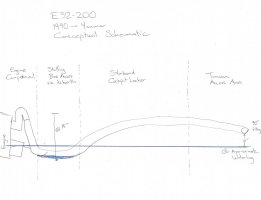

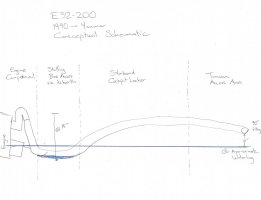

My system looks like this:

The exhaust mixing elbow sits at the rear of the heat exchanger. There are two types of exhaust elbows for this era Yanmar. Mine is the high-loop version designed to address this situation.

I believe the mixing elbow is above the waterline, while the bottom of the engine and the low point of the exhaust pipe is below the waterline. The exhaust line then passes to starboard of the propeller shaft and is visible from the access in the rear quarterberth.

Next the exhaust passes (up, slightly) into the starboard cockpit locker.

From there the exhaust goes around the propane locker cavity and then exits the transom, roughly 10" above the resting waterline.

There is no waterlift muffler. I think there is probably water in the pipe just after the exhaust elbow, but I cannot say it has ever been a problem. Is this one reason why the later production 200's moved over to Yanmar from Universal? Quizas.

I suppose if I managed to hydrolock the engine, I would close the impeller seacock, open the compression levers on the cylinders, run the starter a few times to try to squeeze out as much water as possible, then reverse the order. And then change the oil when I got home.