Knowing what you know now, I think that simply removing that check valve might fix your problem. There is no danger of flooding your boat because the exit through-hull is well above waterline. You will, however get the in-rush of the full volume of water that the check valve was holding back--probably less than a quart.

If pulling the check valve makes the system work, you could be okay. There is no way that pump is going to move 2000gph through a 3/4" hose, however. Whether or not pumping through such a small hose is bad for that motor--I dunno. I'd probably switch to a rule 800 for the long-term if you want to stay with Rule centrifugals.

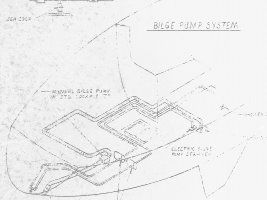

Here's my setup:

.

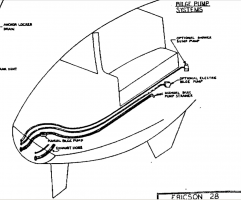

.

I wouldn't worry about minor rises and sags in the line--the general lay of the line is from low to high as it moves up to the through-hull. The rises and sags shown in that video are pretty extreme.

If pulling the check valve makes the system work, you could be okay. There is no way that pump is going to move 2000gph through a 3/4" hose, however. Whether or not pumping through such a small hose is bad for that motor--I dunno. I'd probably switch to a rule 800 for the long-term if you want to stay with Rule centrifugals.

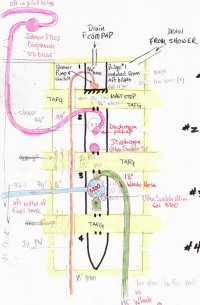

Here's my setup:

.

.I wouldn't worry about minor rises and sags in the line--the general lay of the line is from low to high as it moves up to the through-hull. The rises and sags shown in that video are pretty extreme.

Last edited: