Greetings from a new forum member and relatively new owner of a 1977 Ericson27. While I'm not entirely new to boats I am brand new to boat ownership. I have been lurking and learning on this site for a few months learning and waiting to ask my dumb questions. I love my boat and in many ways its in great shape for it's age. Nice upgrades etc. But it's also a project. I'll spare you my engine and engine replacement questions for another thread, but I'm tackling some easier issues right now.

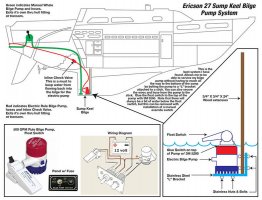

It seems that the original bilge pump design for this boat was a manual bilge pump (only) that exited out stern t-hull. Is that true? Plans I have found seem to indicate as such. I ask because this boat has a "bilge pump to nowhere" or more accurately the end of hose is -- I guess -- supposed to be held over the sink and water exits out the sink t-hull. Seems like a flaw, especially since my manual bilge does not work. I can't imagine sailing the boat and holding the bilge hose over the sink down below.

I can't imagine connecting the bilge directly to the sink hose with a "T". I would like to find an above waterline solution to hook my bilge pump up to. Could I tie it in to the manual bilge hosing back by the stern? Bad idea? Other thoughts?

Thanks. And thanks to this site for keeping despair at bay and keeping my motivation up!

Jay

It seems that the original bilge pump design for this boat was a manual bilge pump (only) that exited out stern t-hull. Is that true? Plans I have found seem to indicate as such. I ask because this boat has a "bilge pump to nowhere" or more accurately the end of hose is -- I guess -- supposed to be held over the sink and water exits out the sink t-hull. Seems like a flaw, especially since my manual bilge does not work. I can't imagine sailing the boat and holding the bilge hose over the sink down below.

I can't imagine connecting the bilge directly to the sink hose with a "T". I would like to find an above waterline solution to hook my bilge pump up to. Could I tie it in to the manual bilge hosing back by the stern? Bad idea? Other thoughts?

Thanks. And thanks to this site for keeping despair at bay and keeping my motivation up!

Jay