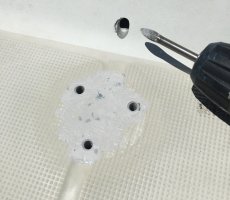

I'm repairing a small section of cabin-top coring damage that occurred under my center/forward dorade guard base. I removed the wet balsa and have a piece of plywood ready to go into its place. I'm pretty familiar handling thickened epoxy, and will smear thickened epoxy around the plywood when I install it.

My questions is, should I also cover the plywood & thickened epoxy with a layer of cloth/mat? If so:

- should I use cloth or mat?

- what weight?

- does the cloth or mat need to be added before the thickened epoxy has set?

- do I need to prep the existing adjacent fiberglass to ensure good adhesion? What's the best way to prep it?

Thanks.

Note to other 32-3 owners: It's worthwhile inspecting the forward "stanchion" base under the center leg of the dorade guard. While the left and right legs sit squarely atop the uniform non-skid surface, the center base bridges two non-skid areas with a recessed, smooth-deck area in between.

The center bolt of my forward stanchion base had almost no sealant under it, and this was the cause of the leak.

My questions is, should I also cover the plywood & thickened epoxy with a layer of cloth/mat? If so:

- should I use cloth or mat?

- what weight?

- does the cloth or mat need to be added before the thickened epoxy has set?

- do I need to prep the existing adjacent fiberglass to ensure good adhesion? What's the best way to prep it?

Thanks.

Note to other 32-3 owners: It's worthwhile inspecting the forward "stanchion" base under the center leg of the dorade guard. While the left and right legs sit squarely atop the uniform non-skid surface, the center base bridges two non-skid areas with a recessed, smooth-deck area in between.

The center bolt of my forward stanchion base had almost no sealant under it, and this was the cause of the leak.

Last edited: