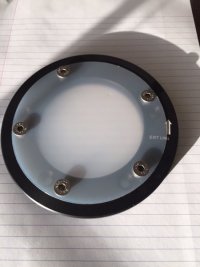

I have 32.2st Harkin Barbarossa winches. I just changed my genoa sheets to 7/16" which is in the middle of the line size that winch is supposed to handle. I when down from 1/2" in an effort to help make tacking go more smoothly. However, the starboard winch does not grip the line...at all. Upon deeper evaluation of the situation it seems that the jaws may be worn down. I emailed Harken and I got an immediate response, but vague. This is what I learned from Harken: [FONT="]"Hi – the top may be adjustable . Take it apart at the top and there should be steps to adjust ."[/FONT]

Ok, taking apart my winches will be the next "first time" learning experience for me. I cannot find in any manuals much more than cryptic references to adjusting the jaws on some models. There is little to no info on the Barbarossa model. they must be a lot older than the PO led me to believe! Does anyone have these models and/or know if they are adjustable? Thanks.

Jay

Ok, taking apart my winches will be the next "first time" learning experience for me. I cannot find in any manuals much more than cryptic references to adjusting the jaws on some models. There is little to no info on the Barbarossa model. they must be a lot older than the PO led me to believe! Does anyone have these models and/or know if they are adjustable? Thanks.

Jay