You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Companionway reflective sheeting

- Thread starter Starduff

- Start date

I'd suggest updating to a common material not available back then.

It's cheaper on Amazon if you are so inclined.

Reflectix 48 in. x 25 ft. Double Reflective Insulation Roll BP48025

Reflectix Insulation has over 20 energy-saving applications for around the home. The list of uses includes crawl space, radiant floor, attic and walls. Our product is easy-to-handle and install. Reflectix

www.homedepot.com

It's cheaper on Amazon if you are so inclined.

David Grimm

E38-200

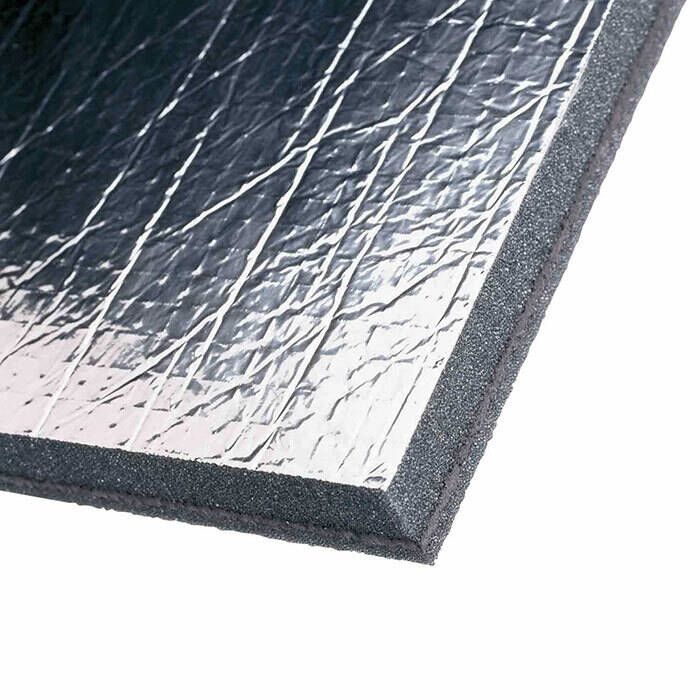

Soundown Sound-Stop Foam Panel with 1lb Barrier Layer

Sound-Stop Acoustic Absorption Materials will reduce noise level and provide thermal insulation when applied to hull walls, inside stateroom bulkhead walls, engine compartments. This is Noise Reduction Enterprises' top-of-the line material. When people us

Also, I have had good success with blankets draped and crammed over the exterior of the engine box, behind the companionway ladder. I'm currently making a custom blanket for that application and will brag it up when finished. Such an exterior sound deadener works well and can be stowed when not required.

Last edited:

I attached an old article I found on Sailboat Engine Considerations. It's interesting, but a bet perfectionist.

Here's an excerpt from page 7:

I've thought about adding more soundproofing and insulation to my engine compartment, but the goal is not to make an airtight space.

Here's an excerpt from page 7:

"All diesel engines need lots of fresh air for combustion. Ideally, a blower wired to the key switch and designed to automatically run and shut off with the engine, should be installed to create a minor vacuum inside the engine space.

The hot air suction hose should be high and aft in the compartment, while the cool air intake should be low and forward, to completely ventilate the engine space. Alternators produce heat when operating, and the fresh, cool air provided by this system will contribute greatly to the service life of all components subject to engine and alternator heat."

I've thought about adding more soundproofing and insulation to my engine compartment, but the goal is not to make an airtight space.

Attachments

David Grimm

E38-200

Kudos Kenneth! Thank you for sharing. I was planning on replacing that leaky copper fuel line this week. Now a stainless exhaust elbow, that would add some "BLING" to the engine compartment!

Kudos Kenneth! Thank you for sharing. I was planning on replacing that leaky copper fuel line this week. Now a stainless exhaust elbow, that would add some "BLING" to the engine compartment!

Tin,I'd suggest updating to a common material not available back then.

Reflectix 48 in. x 25 ft. Double Reflective Insulation Roll BP48025

Reflectix Insulation has over 20 energy-saving applications for around the home. The list of uses includes crawl space, radiant floor, attic and walls. Our product is easy-to-handle and install. Reflectixwww.homedepot.com

It's cheaper on Amazon if you are so inclined.

Thanks much! I will give it a try.

And a big thank you to all. I knew you would come through with great ideas!

Richard

That 3-layer foam referenced above from Defender is like one of the stock noise-reduction products offered at our local heavy equipment vendor. I sometimes still wonder if I should bought it rather than the lighter-weight single layer that I did buy. The factory sound deadener was a single layer with the shiny mylar surface adhered to it. In either case, the engine noise now is greatly reduced -- how much of that is from the new Betamarine being inherently quieter, I do not know. I DO like the result, though!

Actually the original stuff was probably doing OK, except that after the first 20 years the un-sealed edges had allowed deterioration of the foam product, working inwards until most of the old foam was falling off. I had removed the old stuff many years before. (Gawd-Awful mess) Given that the product does break down, slowly, in the presence of heat as well as fumes, replacement after X number of decades might be needed anyway.

After talking to my boat builder friends, I sealed ALL of the sides/edges with a ($) tape before gluing the new foam panel pieces. Lastly, following their advice, I added short screws with large alum. washers, as a sort of "belt & suspenders" approach. You can see this in my engine replacement blog here.

Actually the original stuff was probably doing OK, except that after the first 20 years the un-sealed edges had allowed deterioration of the foam product, working inwards until most of the old foam was falling off. I had removed the old stuff many years before. (Gawd-Awful mess) Given that the product does break down, slowly, in the presence of heat as well as fumes, replacement after X number of decades might be needed anyway.

After talking to my boat builder friends, I sealed ALL of the sides/edges with a ($) tape before gluing the new foam panel pieces. Lastly, following their advice, I added short screws with large alum. washers, as a sort of "belt & suspenders" approach. You can see this in my engine replacement blog here.

Thanks, Loren.That 3-layer foam referenced above from Defender is like one of the stock noise-reduction products offered at our local heavy equipment vendor. I sometimes still wonder if I should bought it rather than the lighter-weight single layer that I did buy. The factory sound deadener was a single layer with the shiny mylar surface adhered to it. In either case, the engine noise now is greatly reduced -- how much of that is from the new Betamarine being inherently quieter, I do not know. I DO like the result, though!

Actually the original stuff was probably doing OK, except that after the first 20 years the un-sealed edges had allowed deterioration of the foam product, working inwards until most of the old foam was falling off. I had removed the old stuff many years before. (Gawd-Awful mess) Given that the product does break down, slowly, in the presence of heat as well as fumes, replacement after X number of decades might be needed anyway.

After talking to my boat builder friends, I sealed ALL of the sides/edges with a ($) tape before gluing the new foam panel pieces. Lastly, following their advice, I added short screws with large alum. washers, as a sort of "belt & suspenders" approach. You can see this in my engine replacement blog here.

I kind of like the "lighter-weight single layer " that you did buy. What was it? Was it similar to what Tin spoke of? The 3-layer foam product concerns me because of the space it might take up in the box of my E-28 companionway. Not much room between it and the Universal Diesel. I may have to investigate with Defender.

Richard

Here's my engine blanket and new noise insulation barrier:

ericsonyachts.org

ericsonyachts.org

E381 - Engine Noise Suppression Upgrade, Ericson 381

I knew a music critic who bought a new high-end turntable and amp and passed me his expensive headphones to demonstrate. I listened and after a while cautiously said, "Joe, I gotta tell you, I hear a hiss." He replied: "If you do, that's your...