This is Jerry Henwood, who in a 45-minute seminar on rigging checks is not to my mind all that irritating, which is more than can be said by other such lecturers.

His points caused me to have yet another look at my own rig, where I was surprised to find several remaining split rings to be replaced with cotter pins "of as large a size as possible." I haven't personally climbed the mast lately (well, ever on this boat), but I intend soon to bring my video camera, with tripod, and zoom in on the spreaders, T-connections, and sheaves. I have found in the past that that can reveal issues requiring a professional inspection.

I recently took off the genoa for repair, and was able to confirm, and then replace, the monel safety wire on the screw-pin halyard shackles (twist-pin or snap shackles are all wrong for working halyards).

Eyeballing our own rigging requires deep suspicion and a magnifying glass, and is only an interim maintenance check. A qualified rigger needs a periodic look, I believe, since I have missed so many issues myself over the years despite an unusually high regard for the mirror.

Here is a T-bolt from the 32-3, which a rigger discovered from a bosun's chair. And an example of a near-invisible hairline crack that requires immediate replacement of any swage.

...

...

The backstay chainplate of the 381 was obvious (although the surveyor never saw it). Interesting view from the side, I think you'll agree.

...

...

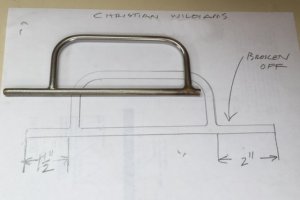

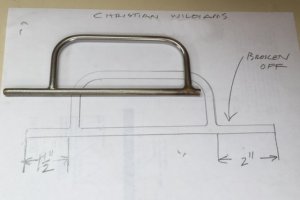

Our standard gooseneck is cast aluminum, elderly, and subject to failure at the stress points. The simple pin for the anchor locker illustrates how any weld is subject to deterioration over time. We are told to view all welds with suspicion.

...

...

His points caused me to have yet another look at my own rig, where I was surprised to find several remaining split rings to be replaced with cotter pins "of as large a size as possible." I haven't personally climbed the mast lately (well, ever on this boat), but I intend soon to bring my video camera, with tripod, and zoom in on the spreaders, T-connections, and sheaves. I have found in the past that that can reveal issues requiring a professional inspection.

I recently took off the genoa for repair, and was able to confirm, and then replace, the monel safety wire on the screw-pin halyard shackles (twist-pin or snap shackles are all wrong for working halyards).

Eyeballing our own rigging requires deep suspicion and a magnifying glass, and is only an interim maintenance check. A qualified rigger needs a periodic look, I believe, since I have missed so many issues myself over the years despite an unusually high regard for the mirror.

Here is a T-bolt from the 32-3, which a rigger discovered from a bosun's chair. And an example of a near-invisible hairline crack that requires immediate replacement of any swage.

...

...

The backstay chainplate of the 381 was obvious (although the surveyor never saw it). Interesting view from the side, I think you'll agree.

...

...

Our standard gooseneck is cast aluminum, elderly, and subject to failure at the stress points. The simple pin for the anchor locker illustrates how any weld is subject to deterioration over time. We are told to view all welds with suspicion.

...

...

Last edited: