The following discussion is relevant to Ericson 30+ owners:

Image 1 - bow after metal cap is removed.

Image 2 - bow port side showing teak filler

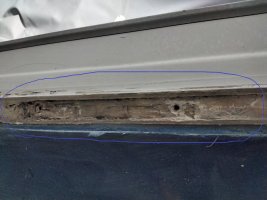

Image 3 - Stern after removing rub rail

The LOA and Beam specs are taken from Sailboat data: https://sailboatdata.com/sailboat/ericson-30

LOA: 29.92 ft

Beam: 10.50 Ft

TACO rub rail Calculation

(Length *2) + (Beam*2)

(30 ft * 2) + (10.5 ft * 2) = 60ft + 21ft = 81 ft

Replacement parts and cost

1’’ X 1/2’’ FLEXIBLE VINYL INSERT

Rub Rail Store / Vinyl Inserts

V12-0303

Part Number Length Color Description

V12-0303BKA50-1 50 feet Black Flexible Vinyl, Black Rub Rail Insert, 1/2"W x 1"H x 50'L

Cost of 2x50 ft sections - 150 + 150 = $300

1-7/8’’ X 1’’ RIGID RUB RAIL

Rub Rail Store / Rigid Vinyl

V21-9602WHA20D

Part Number Length Color Insert Description

V21-9602WHA20D 20 feet Arctic White V12-0303 Rigid Vinyl, Arctic White Rub Rail Insert, 1"W x 1-7/8"H x 20'L

Cost of 5 20 ft sections plus $300 shipping charge - 5* 150 + 300(shipping Charge) = $1050

Total expense - $ 1350

Image 1 - bow after metal cap is removed.

Image 2 - bow port side showing teak filler

Image 3 - Stern after removing rub rail

The LOA and Beam specs are taken from Sailboat data: https://sailboatdata.com/sailboat/ericson-30

LOA: 29.92 ft

Beam: 10.50 Ft

TACO rub rail Calculation

(Length *2) + (Beam*2)

(30 ft * 2) + (10.5 ft * 2) = 60ft + 21ft = 81 ft

Replacement parts and cost

1’’ X 1/2’’ FLEXIBLE VINYL INSERT

Rub Rail Store / Vinyl Inserts

V12-0303

Part Number Length Color Description

V12-0303BKA50-1 50 feet Black Flexible Vinyl, Black Rub Rail Insert, 1/2"W x 1"H x 50'L

Cost of 2x50 ft sections - 150 + 150 = $300

1-7/8’’ X 1’’ RIGID RUB RAIL

Rub Rail Store / Rigid Vinyl

V21-9602WHA20D

Part Number Length Color Insert Description

V21-9602WHA20D 20 feet Arctic White V12-0303 Rigid Vinyl, Arctic White Rub Rail Insert, 1"W x 1-7/8"H x 20'L

Cost of 5 20 ft sections plus $300 shipping charge - 5* 150 + 300(shipping Charge) = $1050

Total expense - $ 1350