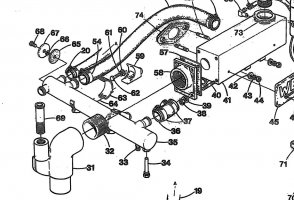

While reviewing pictures for a blog entry on my engine hose replacement, I noticed this on my exhaust manifold flange. I'm going to try and get some better pictures later this week.

I'm guessing it's only partially cracked along the edge. Keeping in mind, I run my engine to get in and out of the harbor on our lake; probably 15 minutes each direction after warm-up. How concerned should I be with this? A new one is around $350 (yikes!). Does this affect the manifold at all? Damage possible? A new one of those is $1200, and that's probably a new engine event. I would rather err on the side of caution, but if I can take it off, patch it with JB Weld and a new gasket, I'd much rather. Or, if it's not a big deal to leave it as-is, even better.

As a side note, I see a lot of the white heat shield wrap on other engines posted here. From what I've read, it helps the exhaust gas exit the system faster. Is that the primary reason? Or are there others? Should I consider installing it? If so, how far do I wrap it? My water is injected in the elbow you see to the left (just off-frame).

If it's a "more info needed" situation, I can sit on this thread until I get more pictures.

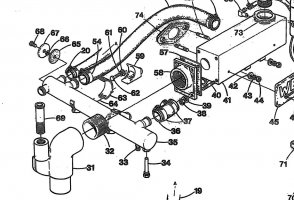

I'm guessing it's only partially cracked along the edge. Keeping in mind, I run my engine to get in and out of the harbor on our lake; probably 15 minutes each direction after warm-up. How concerned should I be with this? A new one is around $350 (yikes!). Does this affect the manifold at all? Damage possible? A new one of those is $1200, and that's probably a new engine event. I would rather err on the side of caution, but if I can take it off, patch it with JB Weld and a new gasket, I'd much rather. Or, if it's not a big deal to leave it as-is, even better.

As a side note, I see a lot of the white heat shield wrap on other engines posted here. From what I've read, it helps the exhaust gas exit the system faster. Is that the primary reason? Or are there others? Should I consider installing it? If so, how far do I wrap it? My water is injected in the elbow you see to the left (just off-frame).

If it's a "more info needed" situation, I can sit on this thread until I get more pictures.