G10 is great stuff, interchangeable with aluminum except much easier to keep painted and join with other parts with epoxy. But carbide tooling is absolutely essential - unless you only want to get partway through your project, and you enjoy the smell of hot metal and scorched G10.

(Which. I. Do. Not.)

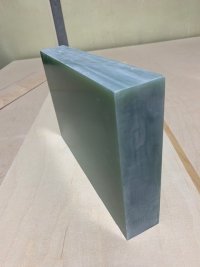

My source for sheets is McMaster.com, but I find small chunks of it at reasonable prices from a guy on eBay in Norfolk, VA who is some sort of fabricator. I use it for backing plates (1/4" thickness), deck core material under stanchions (1/2"), as a base under the deck-stepped mast (1/2"), and (in 3/16" thickness) as the upper layer for deck replacement, with foam in place of the original balsa core. I find it absolutely indispensible in core repair projects because of its enormous strength and ease of placement, and can't imagine why people attempt to build their own upper surface using layers of glass cloth.

My big experiment a few years ago was to create an integral winch base plate and cleat lift for my mainsheet, which is mounted on the cabin top and that I relocated from starboard to port to get out of the way of the halyards. This replicated the functionality of a bent metal plate that came with the boat that remains on the starboard side. It's painted with silver paint, so it looks fairly metal, and has been working perfectly.

This is the best picture of it I could find. Everything from below the winch to the cleat is G10; the built-up portion is several layers of 1/2" rounded rectangular G10 stacked up and epoxied together atop a base of 1/4" G10. The cleat is attached with long through-bolts and countersunk nuts into the bottom of the G10 stack.

EDIT: Oh, I see you're selling your 12" x 8" x 2" chunk. That's going to be useful under somebody's mast.