Stuart 28-2

Member II

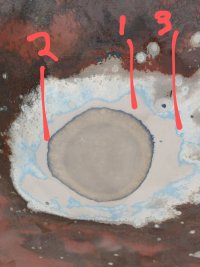

Photo is a blister under repair.

My understanding is the builder sprays gelcoat into the mold. They get the blue stripe by taping that part off and spraying with gelcoat colored white. Then remove the tape and spray with gelcoat colored blue. Then they layer in the fiberglass to produce the hull (simplified due to level of understanding).

I thought they just went down to the water line with gelcoat. This blister is well below the water line. However, just going by the colors and their order, it looks to me like what I label as 1 is the same gelcoat as above water line and what I label as 2 is the same blue as the stripe.

Please comment in whether that is true or something else.

The follow up question is what is the lighter colored blue that I label as 3?

It seems like that is the first layer outside from the white "gelcoat". Is that a barrier coat of some kind that would have been applied by Ericson at build prior to bottom paint?

My understanding is the builder sprays gelcoat into the mold. They get the blue stripe by taping that part off and spraying with gelcoat colored white. Then remove the tape and spray with gelcoat colored blue. Then they layer in the fiberglass to produce the hull (simplified due to level of understanding).

I thought they just went down to the water line with gelcoat. This blister is well below the water line. However, just going by the colors and their order, it looks to me like what I label as 1 is the same gelcoat as above water line and what I label as 2 is the same blue as the stripe.

Please comment in whether that is true or something else.

The follow up question is what is the lighter colored blue that I label as 3?

It seems like that is the first layer outside from the white "gelcoat". Is that a barrier coat of some kind that would have been applied by Ericson at build prior to bottom paint?