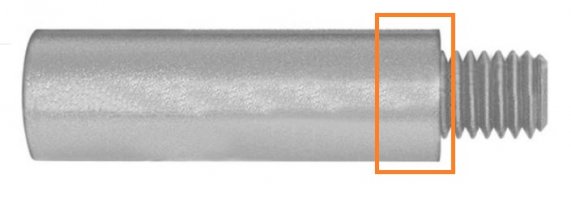

Today was maintenance day... oil change, check the transmission fluid, etc. And then change the pencil zinc in the heat exchanger. Normally a 3-minute job, 2-1/2 of which is spent digging out the 9/16" wrench.

.... and then to find that only part of the pencil zinc came out with the bronze cap.

Arrrgghhh!

I can feel the rest of it in the hole. It's solidly stuck in place. No way that I can think of to get it out. I tried for the better part of two hours. By taking off the end-cap closest to the hole, I can see it... but nothing I tried would persuade it to move, let alone come out. (I didn't want to get too energetic with it for fear it would break loose and move out of reach)

My assumptions at this point, are two:

-- it's probably a pressing problem, as it likely isn't doing much galvanic good in there right now, and

-- it's probably not a good idea to run the motor until it is fixed. If it breaks free in there, not sure where it would go.

So, it looks like my next chore is going to be pulling the heat exchanger. So much for a 3-minute job.

Couple of questions, since I've never done this before

1) It seems pretty clear that the process will involve draining the coolant from the system, disconnecting the 4 hoses, and unbolting the bracket that holds it in place. Anything else I should plan for?

2) Once I've got it out, seems like a good time to have it boiled out. My guess (just from looking through the end cap) is that the zinc is being held in place by accumulated crud, so it's probably past time. I've heard (?) I could take it to a radiator shop and have it cleaned out. Is there a better way?

3) This is an (apparently) original 2" diameter unit. Once it's out... should I think about replacing it with a 3" diameter heat exchanger? I've heard people have done that, but don't know the pros and cons. Or where to get one. Or what to ask for. It occurs to me that the end-cap gaskets should probably be replaced, the port one at least is looking pretty tired. That might be harder to find than a whole new unit, don't know.

4) looking forward to that happy day when all is back together, anything I need to do (other than refilling coolant and such) before firing up the diesel? I've heard about people having high-temp issues resulting from air-bubbles in the system, are there ways to prevent that?

6), oh, and how often do people generally change the pencil zincs? I've been doing it each spring, have never had a problem until today, but I'm wondering if doing it more frequently would help the system stay healthier. Or at least make it so the next one comes out whole.

At this point, I'm frustrated and feel like I don't know what I don't know, any insights appreciated....

Bruce

.... and then to find that only part of the pencil zinc came out with the bronze cap.

Arrrgghhh!

I can feel the rest of it in the hole. It's solidly stuck in place. No way that I can think of to get it out. I tried for the better part of two hours. By taking off the end-cap closest to the hole, I can see it... but nothing I tried would persuade it to move, let alone come out. (I didn't want to get too energetic with it for fear it would break loose and move out of reach)

My assumptions at this point, are two:

-- it's probably a pressing problem, as it likely isn't doing much galvanic good in there right now, and

-- it's probably not a good idea to run the motor until it is fixed. If it breaks free in there, not sure where it would go.

So, it looks like my next chore is going to be pulling the heat exchanger. So much for a 3-minute job.

Couple of questions, since I've never done this before

1) It seems pretty clear that the process will involve draining the coolant from the system, disconnecting the 4 hoses, and unbolting the bracket that holds it in place. Anything else I should plan for?

2) Once I've got it out, seems like a good time to have it boiled out. My guess (just from looking through the end cap) is that the zinc is being held in place by accumulated crud, so it's probably past time. I've heard (?) I could take it to a radiator shop and have it cleaned out. Is there a better way?

3) This is an (apparently) original 2" diameter unit. Once it's out... should I think about replacing it with a 3" diameter heat exchanger? I've heard people have done that, but don't know the pros and cons. Or where to get one. Or what to ask for. It occurs to me that the end-cap gaskets should probably be replaced, the port one at least is looking pretty tired. That might be harder to find than a whole new unit, don't know.

4) looking forward to that happy day when all is back together, anything I need to do (other than refilling coolant and such) before firing up the diesel? I've heard about people having high-temp issues resulting from air-bubbles in the system, are there ways to prevent that?

6), oh, and how often do people generally change the pencil zincs? I've been doing it each spring, have never had a problem until today, but I'm wondering if doing it more frequently would help the system stay healthier. Or at least make it so the next one comes out whole.

At this point, I'm frustrated and feel like I don't know what I don't know, any insights appreciated....

Bruce