Mark David

Member II

Hello All!

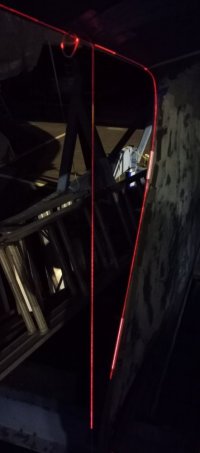

With OtJ adjusted in her cradle, hanging a plumb bob from the bow and confirming with a laser; I believe I have found the vertical baseline and continued it the length of the hull.

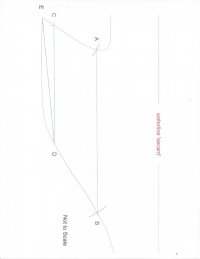

The top of the factory applied gelcoat boot stripe is aesthetically curved, but the bottom edge should be parallel to the waterline = horizontal baseline.

Can anyone offer an alternate or save me from myself??

Thanks!

Mark

With OtJ adjusted in her cradle, hanging a plumb bob from the bow and confirming with a laser; I believe I have found the vertical baseline and continued it the length of the hull.

The top of the factory applied gelcoat boot stripe is aesthetically curved, but the bottom edge should be parallel to the waterline = horizontal baseline.

Can anyone offer an alternate or save me from myself??

Thanks!

Mark