klb67pgh

Member III

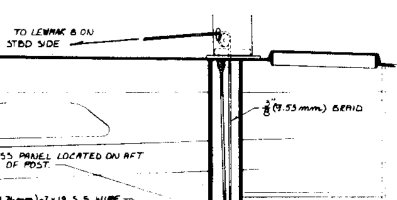

During the Spring of 2022, I redid the bottom of my E25 (sand, fair, barrier coat, bottom paint). I also pulled the centerboard out, repaired it, and replaced the pivot pin and centerboard bushings, and the pendant with dyneema. The centerboard movement was improved, but I thought could be better. Additional investigation had me suspecting the sheeve in the mast step - that project would have to wait until Spring of 2023. I wasn't sure what I was going to get into to remove the mast step, but I was very pleasantly surprised to discover the 2 machine screws and 2 wood screws came out easily, and the mast step popped off with little force. I expected a bed of sealant but found only a bit at each screw hole. When I removed the sheeve for the control line, it came out in 2 pieces. I suspect it was not rotating and I was dragging the line across it. I had difficulty finding a direct replacement - everything online was a bit too wide, or two tall. I found a source that machined a custom sheeve for the application. Apparently I did not take a picture of the new sheeve - I must have been anxious to install it. It was just a hair too wide, but I easily sanded the new sheeve on the belt sander for a perfect fit. I also took the opportunity to remove some old mast wiring and tidy up under the mast step.

The first test was after I launched Awela a few weeks ago. I am now able to winch the centerboard with one hand and not bracing myself against anything for leverage. I should have made this fix the first off season-I thought mast step removal was going to be a real pain. The force to raise the centerboard is probably still a bit more than winching the theoretical Yorkshire Terrier that Roscoe/Oystercatcher calculated on his blog, but I'm happy, and the crew will be happy.

The first test was after I launched Awela a few weeks ago. I am now able to winch the centerboard with one hand and not bracing myself against anything for leverage. I should have made this fix the first off season-I thought mast step removal was going to be a real pain. The force to raise the centerboard is probably still a bit more than winching the theoretical Yorkshire Terrier that Roscoe/Oystercatcher calculated on his blog, but I'm happy, and the crew will be happy.

Attachments

Last edited:

![20230220_191600[1].jpg](/ie/data/attachments/37/37777-08892e55fdc1cab31ab24fe12da3178d.jpg)

![20230220_192302[1].jpg](/ie/data/attachments/37/37778-8143e76da57daa58a12b7003db8aadab.jpg)

![20230226_075859[1].jpg](/ie/data/attachments/37/37779-38c4ad6d55e216949f3821c4d7247776.jpg)

![20230404_195819[1].jpg](/ie/data/attachments/37/37780-1c8d0f3492b1d6b7ef2ef0095a47c3b3.jpg)