to remove core I have used a bent nail and ground the edges sharp... but a roofing nail with three cuts with a grinder or hacksaw, and the edges bent downwards on the leading edge is a really good idea and more easily controlled. No need to go back a full inch... if you are drilling for 1/4" bolts, overdrill to a 1/2" hole, then use the nail or whatever to remove core back another 1/4" or so, then clean out the hole and plug the bottom with tape and fill with thickened epoxy (in a perfect world, first wetting out with neat epoxy with a bent pipe cleaner or whatever), then redrill your 1/4" holes.

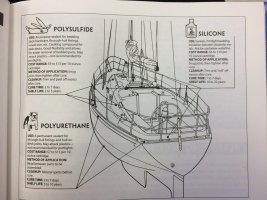

And- it will sound like a broken record... but never ever, as in EVER... use silicone on fiberglass surfaces. The silicone oil will contaminate the fiberglass and nothing will ever stick there again for the life of the boat. Use a polysulphide... many choices.