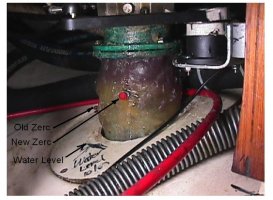

I finally did a chore that has been on hold for a long time. I lubricated the rudder post bearings in our E32-3. The top bearing was easy. I snaked the flexible hose of a grease gun up thru the steering quadrant and pumped in a few strokes. Joy. The lower bearing was more of a chore. The factory lower Zerc fitting (Old Zerc) was mostly covered with fiber glass from the factory. Had probably never been lubricated. After chipping away the glass my pretty heavy duty grease gun could not pump grease thru the Zerc. It was apparently corroded shut. What to do? Observing that the Old Zerc was located in the rudder stock above the lower bearing and above the water line, as well as below the stuffing box I drilled, tapped and screwed in a new Zerc fitting (New Zerc, with red rubber cap). I used epoxy glue to seal and secure the fitting. Then I was able to pump copious quantities of grease into the cavity while turning the wheel back and forth. Oh, it turns so smooth and nice now. Feels So Good!. The whole job took about an hour after I had my head straight on a plan and gathered all the materials and tools. One question you might be wondering about. How did I know the water line level inside the boat before I went to drilling holes? I used a long piece of clear tubing filled with water with one end over the side of the boat into the bay, routed inside the boat to well below water line with the other end above water line. The water level is easily observed in the tube. Kind of a reverse contractors water level. So that's done for this year.