Can't I just disconnect the oil pressure sender and the circuit board? And rely on the oil pressure switch wired directly to the buzzer?

Well, I kind of get it. I think.

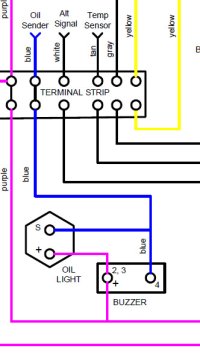

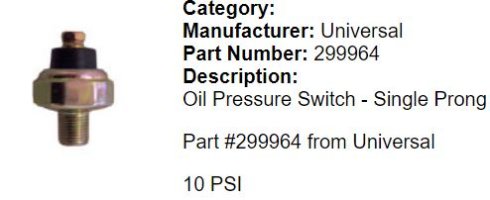

First there's the nomenclature issue--we call these things switches and senders interchangeably when really a switch is just an on/off device while a sender creates variable resistances (ohms) that need to be interpreted by a gauge. Below, #1 and #3 are pressure switches (they connect to separate light/buzzer combinations); #2 is a pressure sender (it connects to an oil pressure gauge--there would be no reason to have a pressure sender without a corresponding pressure gauge).

Seems I've read that most of the pressure switches are set at either 7 or 11 psi. They can't discriminate between low or zero pressure, only whether the pressure is above or below the set threshold psi.

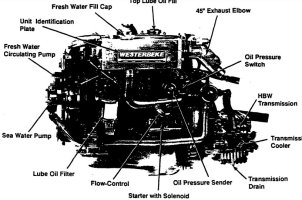

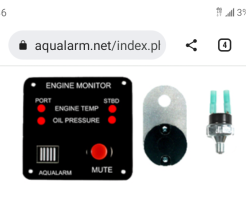

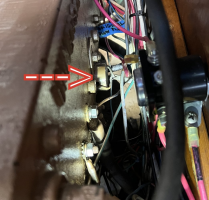

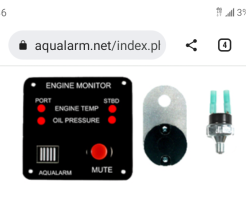

Secondly, the device by the red arrow in your second photo looks more like a block temperature warning switch than a pressure sender. Here is Aqualarm's (the middle device):

Having one of these would explain why you have a circuit board--likely, both your oil pressure switch and your block temp switch were part of a panel like the one above. The circuitry allows both switches to share a single buzzer and mute button, and allows a triggered switch/alarm to be silenced while the other switch/alarm is still armed.

Third, note in my first photo above that there are two types of pressure switches; double pole (#1), and single-pole (#2).

The

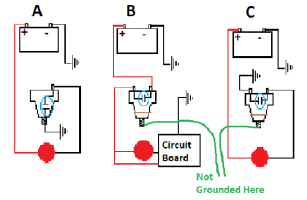

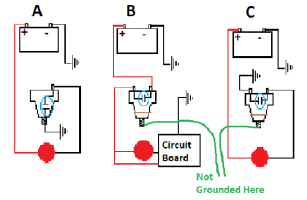

single-pole switch can only be used in the negative side of the circuit. The second "pole" is the switch body itself, which screws into and, thus, grounds itself to the engine block. This is what Ericson typically used to ground the oil pressure idiot light (which pulled its positive power from a wire off of the engine panel). See "A" below:

In a

double-pole switch, the two poles at the top are insulated from the metal body itself, so this switch can be used in the positive side of a circuit. A double pole switch, installed in the positive side of a circuit, would be typical in a circuit-board type alarm setup because this is what provides power to the circuit board. See "B" below:

So, to finally answer your question,

"Can't I just disconnect the oil pressure sender and the circuit board? And rely on the oil pressure switch wired directly to the buzzer?" Yes, it should be that easy. If it's not, my guess is that you are trying to build circuit

A, below, (the Ericson OEM setup) using a double-pole switch, which would leave the circuit ungrounded. Try grounding one of the poles to your ground bus bar (as in

C, below). Or, try using a single-pole pressure switch.

Finally, if your buzzer/light kept coming on below 1500 rpm, hopefully, it was just a bad pressure switch. If not, it could be that you actually have low oil pressure below 1500 rpm. When starting my engine cold, I read near 40 psi. When warmed up to 185 deg, pressure drops to about 30+/- psi. But, I do remember when I was running 10W-30 oil, in a hot engine, at low idle speeds (say below 800 rpm), I was surprised the needle would go well below 20psi. After switching to 15W-40 oil, the pressure stays a little higher at low rpm.

Also, if you have a block temperature switch installed (looks like there's one on your exhaust manifold tank), you can still keep it hooked up even if you rip out the circuit board. It's just a temperature switch--it closes above (usually) about 200F to complete a circuit. Hook it up to a separate buzzer/light combination and you'll have over-temp warnings as well. It can operate completely independent of the water temperature sender & gauge circuitry.