Prairie Schooner

Jeff & Donna, E35-3 purchased 7/21

Can-O-Worms Alert

Can-O-Worms AlertThis is related to our ongoing prop shaft strut rebed project ( https://ericsonyachts.org/ie/threads/e35-3-prop-shaft-strut-a-look-inside-and-a-zinc-question.19649/ ), but not about the strut.

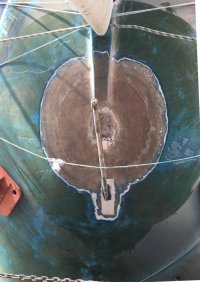

While grinding down the scarf for the reinstall I started to really look at the shaft. It seems to me that it’s off center. I understand that on some boats this was done to compensate for prop walk. Is that the case here, or has the boat been living with a wonky shaft all these years?

Also, I’m surprised (dismayed, alarmed, ?) about how much putty that has been used around the strut and shaft. Does all that the shmutz around the shaft log worry any of you?