You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rudder bushing question

- Thread starter bsangs

- Start date

bsangs

E35-3 - New Jersey

Took nearly six mini grease canisters (3 oz each) of Green Grease and one of West Marine grease before it finally starting squeezing through the top. Previous owner said he never greased it, so God knows when the last time any was applied. My wrists and forearms enjoyed the workout. Hope it keeps any water at bay this season.

jtsai

Member III

Is it easy to tell when the drill bit penetrated the fiberglass tube? Approximately how thick is the tube?Gave this zerk replacement project a go today Christian, and thank you for posting in such detail. Was unable to find a 1/2 inch, unfortunately, so my grease pumping tomorrow will take longer than yours, I’m sure. Hope it works.

View attachment 46621

bsangs

E35-3 - New Jersey

I took Christian’s advice, and plunged right in with the drill, remembering how difficult it was to drill a simple hole in my 1” stainless steel cockpit rail. Considering that, I wasn’t worried about penetrating the stainless steel rudder post. The drill cut through the glass, and I could tell by feel once it hit the stainless post. I then lowered a lighted mirror down to get a better view of the hole and could see the post. Not sure exactly how thick it was, but I wouldn’t think more than two inches.Is it easy to tell when the drill bit penetrated the fiberglass tube? Approximately how thick is the tube?

bsangs

E35-3 - New Jersey

Should note @jtsai that I also used a larger bit to just get deep enough for the zerk threads, then finished with a smaller bit to the rudder post. (As Christian suggested). I did need to tap the zerk in lightly with a hammer to get it flush, as the best drill bit I had was slightly smaller that the thread size.I took Christian’s advice, and plunged right in with the drill, remembering how difficult it was to drill a simple hole in my 1” stainless steel cockpit rail. Considering that, I wasn’t worried about penetrating the stainless steel rudder post. The drill cut through the glass, and I could tell by feel once it hit the stainless post. I then lowered a lighted mirror down to get a better view of the hole and could see the post. Not sure exactly how thick it was, but I wouldn’t think more than two inches.

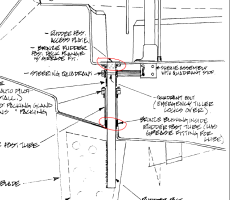

I've been planning to do this for a while, but still have a few questions. The tip on the larger bit for the threads and smaller bit clears up most of my questions, but the part I'm still scratching my head on is the placement of the Zerk fitting. The original design looked to have the fittings located where they would lube the bushings:

My upper fitting is great and accepted grease with no problem. The lower one doesn't resemble a fitting of any kind let alone a zerk. It doesn't' even look like something I can replace. So, is the installation of a new zerk in the fiberglass rudder tube a work around to create a water dam or does it still lubricate the bushing? Has anyone been successful with replacing the lower zerk?

BTW, I wonder how many hours of frustration @Christian Williams has saved people on this forum by going down this path first and finding the fix. @bsangs, it looks like your rudder bearing seal has given up it's hold and would leak regardless of the state of the packing material. One of the previous owners of my boat wasn't lucky enough to have Cristian's blog as a guide and spent some time down there fiber glassing the packing gland to the rudder tube. They were a bit careless with their work and ended up wrapping glass between the two pieces, above the whole fitting, and around the bolts.

My upper fitting is great and accepted grease with no problem. The lower one doesn't resemble a fitting of any kind let alone a zerk. It doesn't' even look like something I can replace. So, is the installation of a new zerk in the fiberglass rudder tube a work around to create a water dam or does it still lubricate the bushing? Has anyone been successful with replacing the lower zerk?

BTW, I wonder how many hours of frustration @Christian Williams has saved people on this forum by going down this path first and finding the fix. @bsangs, it looks like your rudder bearing seal has given up it's hold and would leak regardless of the state of the packing material. One of the previous owners of my boat wasn't lucky enough to have Cristian's blog as a guide and spent some time down there fiber glassing the packing gland to the rudder tube. They were a bit careless with their work and ended up wrapping glass between the two pieces, above the whole fitting, and around the bolts.

bsangs

E35-3 - New Jersey

BTW, I wonder how many hours of frustration @Christian Williams has saved people on this forum by going down this path first and finding the fix. @bsangs, it looks like your rudder bearing seal has given up it's hold and would leak regardless of the state of the packing material. One of the previous owners of my boat wasn't lucky enough to have Cristian's blog as a guide and spent some time down there fiber glassing the packing gland to the rudder tube. They were a bit careless with their work and ended up wrapping glass between the two pieces, above the whole fitting, and around the bolts.

Wait, are you saying I just wasted my time and energy with this project @trickdhat?

Not at all. Actually the opposite and I plan on doing the same. Christian detailed his work that started with resecuring the packing gland and repacking it but still ended up with a leak. It was the work you've done that actually stopped the water coming in. I was just saying his blog saved you and others from focusing on the packing gland and still having a leak.Wait, are you saying I just wasted my time and energy with this project @trickdhat?

I noticed that, too. The grease is coming out of the joint between the bronze and the tube. That seal, bronze to tube, was created by the factory with 5200, there is no mechanical fastening. If the bronze rotates or lifts easily, it will need to be re-bedded, which is a different issue.

But probably the grease will fill the gaps.

But probably the grease will fill the gaps.

bsangs

E35-3 - New Jersey

Whew! Yeah, his post was invaluable. I’d have never had the confidence level to do such a job this soon in my boat ownership life without having come across it.Not at all. Actually the opposite and I plan on doing the same. Christian detailed his work that started with resecuring the packing gland and repacking it but still ended up with a leak. It was the work you've done that actually stopped the water coming in. I was just saying his blog saved you and others from focusing on the packing gland and still having a leak.

Yes. The drill bit will hit the stainless rudder post and stop. It won’t hurt anything. The rudder tube is probably 1/4” thick, maybe a bit less?Is it easy to tell when the drill bit penetrated the fiberglass tube? Approximately how thick is the tube?

I doubt that the lower grease fitting was ever installed in the lower bearing itself (vs the upper bearing). My lower bearing seemed to be about 6" tall. Considering that it extends from below the shallow "skeg," through the skeg, then the thickness of the hull, then the built-up base of the rudder tube, I wouldn't think there would be much accessible bearing height above that to support a zerk. More likely, the lower zerk was installed in the rudder tube itself.The original design looked to have the fittings located where they would lube the bushings:

bsangs

E35-3 - New Jersey

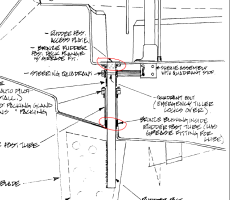

Anyone have a suggestion for clearing a jammed zerk fitting? At least I think that's the problem. The existing upper zerk will not accept any grease from my gun. It's a royal pita to access it for me, and when I finally had a successful coupling, the grease gun wouldn't pump. Took it off, made sure it was working properly, spent another 10 minutes fumbling around to make a connection, same thing. Took the gun apart, reassembled, same thing. Swore a blue streak for 20 minutes, tried again, bubkas. On the surface, the zerk looks to be in perfect shape. I fear it's seized/blocked by old dried up grease. Any other way to get grease in that area if I cannot clear the damn thing?If anybody reading this in the next ten years arrives here because of a sloppy rudder, which clunks when tacking, first check the top rudder-post bearing bolted to the cockpit floor. Typically that bearing* gets loose, causing rudder wobble not related to the bottom bearing at all.

The issue can't be seen from the cockpit, but if that's it, a crawl under to tighten the bolts is an instant fix.

*"Bronze rudder post deck flange w/grease fitting"

View attachment 45618

Jerry VB

E32-3 / M-25XP

Did you take the zerk off and verify it was working properly?The existing upper zerk will not accept any grease from my gun. It's a royal pita to access it for me, and when I finally had a successful coupling, the grease gun wouldn't pump. Took it off, made sure it was working properly, spent another 10 minutes fumbling around to make a connection, same thing.

My experience was that the spring inside the zerk was rusted which prevented the checkball in the zerk from accepting grease. I used a socket and a couple of extensions to reach the zerk to unscrew and replace it.

I have a E32-3 and don't know how it compares to an E35-3 for zerk access. On my boat, I found I could see and access the upper zerk fairly easily (for a boat definition of "easily") after I emptied the aft lazerette and crawled in. After doing that, my eyes were roughly at zerk level and my arms bent the right way to access it.

bsangs

E35-3 - New Jersey

No, I didn’t. Might have to. Unfortunately my zerk access is severely limited. Barely have enough room to get the rubber grease gun tube lined up. The zerk faces forward, and the previous owner replaced the original pedestal. The phalanx of bolts protruding down makes an already difficult task even harder. I can only “access” it from the starboard lazaret, the wall of which has my AIS & Garmin boxes attached to it, making that problematic too. No access to it from the rear lazaret, for my body anyway. 6-feet tall with broad shoulders are good for many things in life, but getting inside the guts of a 1985 Ericson ain’t one of them.Did you take the zerk off and verify it was working properly?

My experience was that the spring inside the zerk was rusted which prevented the checkball in the zerk from accepting grease. I used a socket and a couple of extensions to reach the zerk to unscrew and replace it.

I have a E32-3 and don't know how it compares to an E35-3 for zerk access. On my boat, I found I could see and access the upper zerk fairly easily (for a boat definition of "easily") after I emptied the aft lazerette and crawled in. After doing that, my eyes were roughly at zerk level and my arms bent the right way to access it.

Or you can leave the old one as it is and install a new Zerk in a (somewhat) more reachable position.

That does require working with a drill in the tight space, but otherwise not very difficult.

That does require working with a drill in the tight space, but otherwise not very difficult.

bsangs

E35-3 - New Jersey

Might be my best bet. Simple, but won’t be as easy as drilling for the lower one. Not sure if I’ll still fasten it with epoxy, or try to tap threads.Or you can leave the old one as it is and install a new Zerk in a (somewhat) more reachable position.

That does require working with a drill in the tight space, but otherwise not very difficult.

Tapping threads in the lower rudder tube is difficult only because the tubing wall is thin and the tap hits the rudder post before going very deep.

Tapping the upper bronze bearing likely wouldn't be too bad but I wouldn't do it without removing the bearing or rudder. Otherwise, I'd fear metal shavings are going to wind up on the bearing face.

Tapping the upper bronze bearing likely wouldn't be too bad but I wouldn't do it without removing the bearing or rudder. Otherwise, I'd fear metal shavings are going to wind up on the bearing face.

Seems like a few of us are on the same zerk program right now!

Look forward to hearing how it goes for everyone!

Look forward to hearing how it goes for everyone!