PANorth

Member II

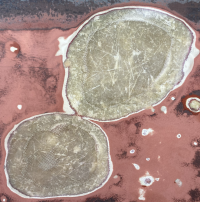

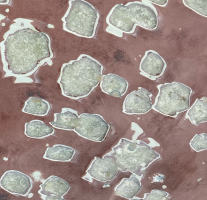

We are in the midst of a major hull repair job after finding abundant blisters under the bottom paint on our new-to-us 1982 E38. I posted about this in the fall before we removed the bottom paint. It didn't look quite so bad then.

Less than a dozen blisters reached the laminate, and none seemed to penetrate. 90%+ were into the chop layer, and the rest are tiny and just below the gelcoat. The biggest is about 6 inches across, though before we are done grinding I am sure many will blend together. Is there a rule of thumb about filling these groundout voids? I assume some will require layers of cloth, some just thickened epoxy and (dare I hope) some just fairing. How do I decide which gets what?

Are there any other things to consider when there are abundant blisters below the water line? See photo.

Less than a dozen blisters reached the laminate, and none seemed to penetrate. 90%+ were into the chop layer, and the rest are tiny and just below the gelcoat. The biggest is about 6 inches across, though before we are done grinding I am sure many will blend together. Is there a rule of thumb about filling these groundout voids? I assume some will require layers of cloth, some just thickened epoxy and (dare I hope) some just fairing. How do I decide which gets what?

Are there any other things to consider when there are abundant blisters below the water line? See photo.