Like to get some input on any possible issues. I have read through past threads but did not find a path to my problem.

History:

- Last Year Late Summer / Early Fall; out of the blue, my engine would not start with no sign of issues. I ended up bleeding the fuel and notice air bubbles so I kept trying to track down the leak. Eventually I could get it running but the air bleed curling knob had to be partially open but when motoring, it would loose power and stall out; mainly due to that I was starving the engine with fuel as the curling knob was directing fuel back to the tank, as designed. After several days over a few weeks, I notice when I slightly pushed on a fuel line from the secondary filter to the injector pump, diesel would spray out within a finest pin hole. I replaced the small fuel line and it ran for a few weeks until I winterized / hauled out.

- Last week during my spring launch, my engine would not start. long and short, I tracked down a leak at the tank copper connection tube to the tank, as it was crinkled and was dripping fuel. Looked like the hole that was put in the plywood bulkhead near the tank was too small and the line pushed on the small opening and developed a leak. I removed the copper line and associated fittings and replaced with a rubber fuel line running from the tank to the Racor fuel filter. Bleed the system at the secondary filter, at the curling knob by removing the nut and ultimately, I had to also crack one of the injector nuts. got it to start and motored to my marina, 3 hours away and ran fine.

- Now. This past weekend, I attempted to start the engine and did not start nor did it even tried. Just turned over. So I went back through the fuel system and notice that the hose clamps that I put on the day I splashed and worked on it into the night, was just slightly too large (solid band type clamps) and did not create a tight fitting. I said... ok, so I installed new hose clamps and checked all other connections and all seem good.

I bled the air from the fuel system. First bleed bolt at the secondary filter came out like a shot - did not see air bubbles.

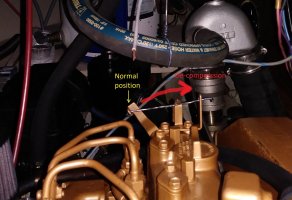

Second bleed bolt at the curling knob, removed the nut where it connects as the curling knob does not work great for bleeding, fuel came out.

Did not start.

Loosen the top and first injector nut, fuel was dripping out (with the fuel pump on).

Did not start.

Because the first bleed bolt at the secondary fuel filter came out with no bubbles and came out like a shot, I am ruling out leak in the first fuel filter, pump and anything behind this point.

When turning the engine over this last time, it would just turn over without any firing attempt.

Any thoughts, input, ideas....? Perhaps I hit something, could there be something else going on here...

History:

- Last Year Late Summer / Early Fall; out of the blue, my engine would not start with no sign of issues. I ended up bleeding the fuel and notice air bubbles so I kept trying to track down the leak. Eventually I could get it running but the air bleed curling knob had to be partially open but when motoring, it would loose power and stall out; mainly due to that I was starving the engine with fuel as the curling knob was directing fuel back to the tank, as designed. After several days over a few weeks, I notice when I slightly pushed on a fuel line from the secondary filter to the injector pump, diesel would spray out within a finest pin hole. I replaced the small fuel line and it ran for a few weeks until I winterized / hauled out.

- Last week during my spring launch, my engine would not start. long and short, I tracked down a leak at the tank copper connection tube to the tank, as it was crinkled and was dripping fuel. Looked like the hole that was put in the plywood bulkhead near the tank was too small and the line pushed on the small opening and developed a leak. I removed the copper line and associated fittings and replaced with a rubber fuel line running from the tank to the Racor fuel filter. Bleed the system at the secondary filter, at the curling knob by removing the nut and ultimately, I had to also crack one of the injector nuts. got it to start and motored to my marina, 3 hours away and ran fine.

- Now. This past weekend, I attempted to start the engine and did not start nor did it even tried. Just turned over. So I went back through the fuel system and notice that the hose clamps that I put on the day I splashed and worked on it into the night, was just slightly too large (solid band type clamps) and did not create a tight fitting. I said... ok, so I installed new hose clamps and checked all other connections and all seem good.

I bled the air from the fuel system. First bleed bolt at the secondary filter came out like a shot - did not see air bubbles.

Second bleed bolt at the curling knob, removed the nut where it connects as the curling knob does not work great for bleeding, fuel came out.

Did not start.

Loosen the top and first injector nut, fuel was dripping out (with the fuel pump on).

Did not start.

Because the first bleed bolt at the secondary fuel filter came out with no bubbles and came out like a shot, I am ruling out leak in the first fuel filter, pump and anything behind this point.

When turning the engine over this last time, it would just turn over without any firing attempt.

Any thoughts, input, ideas....? Perhaps I hit something, could there be something else going on here...