We recently had a raw water pump impeller failure causing the engine (M25 Universal) to overheat. As it turned out it was the rubber part of the impeller that got somehow disconnected from its core (a medal cylinder). In other words, the connection between the two parts, which should have been solid, allowed for slippage between the two. (Not sure how the manufacturer secured the link between two parts to form one unit, glued?) The rubber part looked still like new so this must have been a mechanical failure and/or designer flaw. Not sure if the impeller was an aftermarket unit bought online. After inquiring with West Marine it appears that recently there have been similar reports of such a failure. Caveat emptor!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The rubber part of raw water impeller detaching from its core (a metal cylinder)

- Thread starter Thalassa

- Start date

Brand unknown, right? Well, I suppose weird failures like that are why we carry a spare or two.

Good catch on the overheating. There are boat owners who don't even realize they have a temperature gauge, much less monitor it.

Good catch on the overheating. There are boat owners who don't even realize they have a temperature gauge, much less monitor it.

Chris Martz

New Member

I hope I can help here. After buying my Ericson 323 in 2018 I was experiencing occasional episodes where the raw water would suddenly not not exit boat at the stern, which is difficult to see by the way and my engine temperature would rise quickly. Once I lucked out when my dock neighbor noticed steam exiting where the raw water would normally exit. First I check the raw water strainer which was clean and full of water and then made sure the through haul under the boat was clear of any debris. Next, I opened the bleed nut on the Oberdorfer raw water pump and noticed that water was not streaming out. I then opened up the pump and found that the newer impeller which I replaced right after purchasing the boat had failed as mentioned in the blogs above. I again lubricated and replaced the impeller with an extra I had purchased and was able to get the raw water flowing again. Weeks later and the same problem occurred all over again. I finally discussed with my mechanic and he suggested we replace the raw Oberdorfer water pump and at the same time we replaced the raw water hoses and the through hull fitting. Upon removing the through hull nipple and hose, we found it to be almost entirely blocked and the hose was cracked at the bend. It has now been nearly a year and I have not had any more issues with the raw water system. In fact, it may not have been necessary to replace the raw water pump at all, but now I have an extra pump.

Christian - It is surprising that the 80's Ericson 323's do not have a overheating alarm to help avoid overheating that could easily and quickly destroy a very expensive diesel engine. To make matters worse because of the reverse transom, it is almost impossible to visually check if the raw water is flowing from the cockpit while underway. In fact, my prior 78 Ericson 27 at least had a visible cockpit red light which would come on if I forgot to open the through hull before heading out. Are you aware of any aftermarket solution to add an overheating alarm for the 323? By the way, I have really enjoyed reading your book Alone Together, and learned so much from you experiences. Thank you.

Chris Martz

87 Ericson 323

M25XP

Christian - It is surprising that the 80's Ericson 323's do not have a overheating alarm to help avoid overheating that could easily and quickly destroy a very expensive diesel engine. To make matters worse because of the reverse transom, it is almost impossible to visually check if the raw water is flowing from the cockpit while underway. In fact, my prior 78 Ericson 27 at least had a visible cockpit red light which would come on if I forgot to open the through hull before heading out. Are you aware of any aftermarket solution to add an overheating alarm for the 323? By the way, I have really enjoyed reading your book Alone Together, and learned so much from you experiences. Thank you.

Chris Martz

87 Ericson 323

M25XP

Are you aware of any aftermarket solution to add an overheating alarm for the 323?

Check out Aqualarm: https://aqualarm.net/exhaust-engine-monitorssensors-c-5/

Lots of options. I went with the #20322 kit.

I think this blog covers those details: https://ericsonyachts.org/ie/ubs/mariah-part-iv-engine-monitoring-systems.553/

If you have any other questions, let me know.

If you have any other questions, let me know.

Thanks for posting this, Ken. I've been looking at the Aqualarm stuff, too. I checked out your blog post and I'm curious, what does the back of the panel look like? How does it actually all hook up? (I'm a visual guy)I think this blog covers those details: https://ericsonyachts.org/ie/ubs/mariah-part-iv-engine-monitoring-systems.553/

Has anyone used their flow detector? It seems like it would catch problems even earlier than the engine or exhaust getting hot.

I checked out your blog post and I'm curious, what does the back of the panel look like? How does it actually all hook up? (I'm a visual guy)

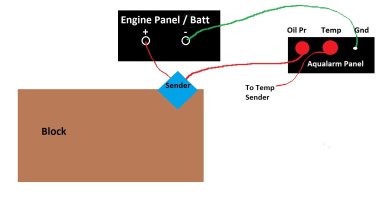

I don't have any pictures of the back side. It was just three wires (either short leads, or hooked up to a small terminal strip--I can't remember which). One positive lead was for the heat sensor, one positive for the oil pressure, and a ground for the panel.

Oh, okay. Nothing complicated then, huh? I guess really the sensors are just closing a contact and completing the circuit, right? So when that happens, the piezo gets powered and the indicator light goes on. I'm probably overthinking this.One positive lead was for the heat sensor, one positive for the oil pressure, and a ground for the panel.

Yep, that's it. But it is different from the Universal oil pressure sender/light. On the OEM setup, the pressure sensor is on the ground wire. That's why it only has one lead--it grounds itself to the block by its threaded body to complete the circuit's ground (below something like 7psi).Oh, okay. Nothing complicated then, huh? I guess really the sensors are just closing a contact and completing the circuit, right? So when that happens, the piezo gets powered and the indicator light goes on. I'm probably overthinking this.

Both of the aqualarm sensors have two leads because they switch the positive side in the circuit rather than completing the ground. The aqualarm panel itself has a common ground for all the devices on the panel.

Note, the "mute" button is nice to kill the buzzer, say, any time you want the engine panel powered without the engine running (powering the glowplugs, bleeding fuel lines, or panel troubleshooting).

Also, there's no need to build an oil pressure manifold as I did (I just did that to add an oil pressure sensor & gauge). You can just swap out the aqualarm pressure switch for the factory one. Be aware though that the factory threads are BSP (British Standard Pipe) while the Aqualarm oil pressure switch will be NPT. Some people use them interchangeably but you can buy a BSP-NPT adaptor to play it safe. That's what I did.

Last edited: