Scyph

Member I

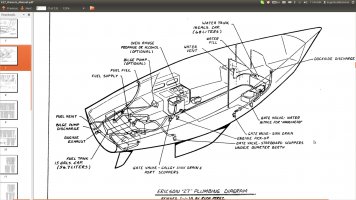

Finally made it to my boat. Still figuring things out. But... of all the things to defeat me, the one that did is the bilge pump. The electric one is broken. The manual pump is supposed to be... somewhere... inside the portside locker (diagram).

I have a handle sticking out from the inside into the cockpit, but I don't see a bigle hose connected to the handle like the pump is supposed to have in the diagram (photo). When I start pumping, the water doesn't come out. Should I pump longer? The previous owner told me that it takes a while for the water to start coming out, because first you need to pump out all the air.

I have a handle sticking out from the inside into the cockpit, but I don't see a bigle hose connected to the handle like the pump is supposed to have in the diagram (photo). When I start pumping, the water doesn't come out. Should I pump longer? The previous owner told me that it takes a while for the water to start coming out, because first you need to pump out all the air.

Attachments

Last edited: