Rick R.

Contributing Partner

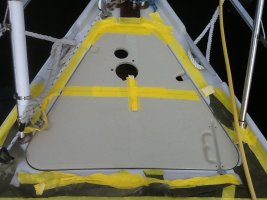

Finally got around to starting the installation of the Maxwell RC8-8 Windlass. I have a boat builder friend doing the glass work next week so I thought I would go ahead and pre-wire the entire project. Glad I did! It took a couple days.

Ordered the the wire from BestBoatwire.com and their prices are much less than others. One problem though, while they sent the 60' of #2 AWG and the terminals I ordered, they neglected to include the 200' of 16 gauge wire. When I called they seemed like they were in no hurry to rectify the situation. Thankfully, a buddy of mine had 100' of 16 on a spool.

I looked into running the wire from the battery box aft/port above the vinyl headliner to the vberth but I was afraid that it would be too heavy and make the headliner sag. I decided to run through the hanging locker (where our Mermaid AC lives), through the two cabinets and along the port side shelf where the ductwork runs forward. We then drilled two holes through to th vberth where the wire runs alongside the cushions. I then goes into the forward hold where the solenoid is mounted.

I wired an aftermarket remote switch and mounted the Maxwell switch in the cockpit. The breaker is mounted in the aft cabin.

I will make a trim cover for the wire in the berth.

*Side note: The guy who helped me commented several times on how well the Ericson is built. When we drilled for the cockpit switch, he couldn't beleive how thick the fiberglass was.

Here re are some photos of my progress.

Ordered the the wire from BestBoatwire.com and their prices are much less than others. One problem though, while they sent the 60' of #2 AWG and the terminals I ordered, they neglected to include the 200' of 16 gauge wire. When I called they seemed like they were in no hurry to rectify the situation. Thankfully, a buddy of mine had 100' of 16 on a spool.

I looked into running the wire from the battery box aft/port above the vinyl headliner to the vberth but I was afraid that it would be too heavy and make the headliner sag. I decided to run through the hanging locker (where our Mermaid AC lives), through the two cabinets and along the port side shelf where the ductwork runs forward. We then drilled two holes through to th vberth where the wire runs alongside the cushions. I then goes into the forward hold where the solenoid is mounted.

I wired an aftermarket remote switch and mounted the Maxwell switch in the cockpit. The breaker is mounted in the aft cabin.

I will make a trim cover for the wire in the berth.

*Side note: The guy who helped me commented several times on how well the Ericson is built. When we drilled for the cockpit switch, he couldn't beleive how thick the fiberglass was.

Here re are some photos of my progress.

Attachments

Last edited: