Good idea on placement and I wonder why it wasn’t done that way. What would give the tech the idea to go back and forth across all that space instead of making the cleanest line between the two ends?

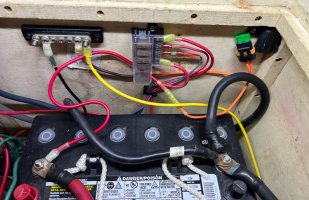

In the tech’s defense I think what you see draped over the battery negative is Jeff’s drawing showing the connection between the orange wire and the red coming off the battery. It’s too long and it’s unsecured, but I think it runs behind the battery and not over the top of it.

Somebody I know with a lifetime of experience on boats recently said he’s never finished a project without immediately realizing he could have done something differently and better