Puget sailor

Member II

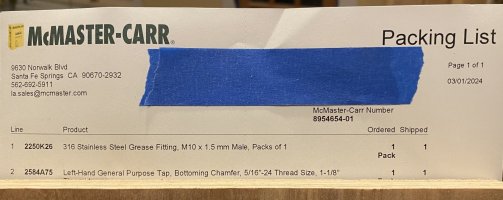

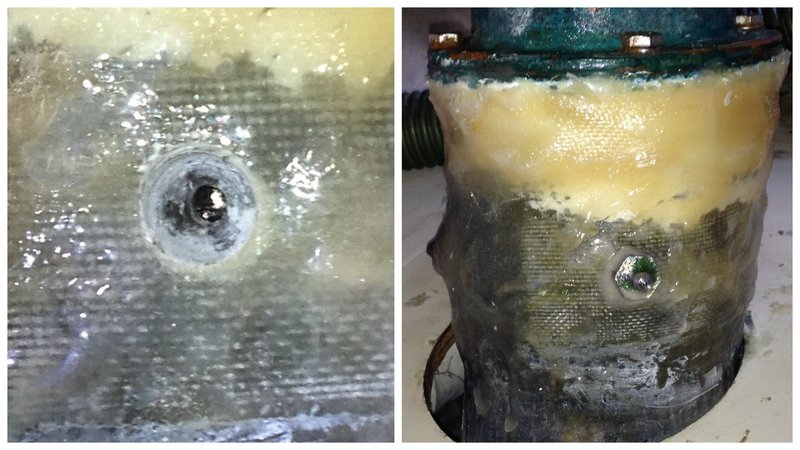

One thing on my list for spring. My original rudder tube grease fitting is just a little rust stain clogging its hole. A replacement by a previous owner seems to be about halfway to that same state of decay. I found 316 stainless grease fittings at McMaster-Carr. Topping up that grease to prevent leaks is routine maintenance on the 32-3, and likely other Ericsons too. Pictures of part and it’s ordering info for convenience. It’s metric threaded, so likely need to drill and tap new hole.