I'm lazy and interested in technology. That can be an expensive combination.

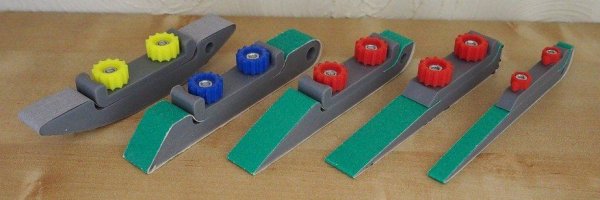

I currently have the boom pulled apart in preparation for painting and the current task at hand is cleaning up the boom ends. Most of the large easily accessible surfaces cleaned up easily with a sander. Now I'm left with the detail sections.

I've been looking for a media blaster and found a company that specializes in dry ice blasting. I called to request a quote and they said they didn't recommend dry ice blasting because itvwasnt abrasive enough, but they offer a laser cleaning service that may help. He hadn't worked on a sailboat before, so he was excited to try and potentially open up a new market.

Unfortunately it didn't work. The laser removed the paint week, but left the corrosion below want removed and would still require sanding. It was interesting to watch and might have some other applications on our boats. The dry ice blasting might be a good solution for bottom paint and could potentially be an envirinmently friendly alternative. I told him I'd give him a call next time we're out of the water if he wanted to give it a try.

So, now I'm back to hand work with a dremel. My experience with a few manufactures of wire wheels is horrible. I haven't found one that lasts longer than a few minutes. I went through a box of 50 cleaning and painting the transmission and ended up with tiny wires impeded in my cloths and exposed skin. Not fun. I didn't learn my lesson and tried again on the mast afew days ago with the same results. Does anyone have a recommendation for a more reliable wire wheel for a dremel?

I currently have the boom pulled apart in preparation for painting and the current task at hand is cleaning up the boom ends. Most of the large easily accessible surfaces cleaned up easily with a sander. Now I'm left with the detail sections.

I've been looking for a media blaster and found a company that specializes in dry ice blasting. I called to request a quote and they said they didn't recommend dry ice blasting because itvwasnt abrasive enough, but they offer a laser cleaning service that may help. He hadn't worked on a sailboat before, so he was excited to try and potentially open up a new market.

Unfortunately it didn't work. The laser removed the paint week, but left the corrosion below want removed and would still require sanding. It was interesting to watch and might have some other applications on our boats. The dry ice blasting might be a good solution for bottom paint and could potentially be an envirinmently friendly alternative. I told him I'd give him a call next time we're out of the water if he wanted to give it a try.

So, now I'm back to hand work with a dremel. My experience with a few manufactures of wire wheels is horrible. I haven't found one that lasts longer than a few minutes. I went through a box of 50 cleaning and painting the transmission and ended up with tiny wires impeded in my cloths and exposed skin. Not fun. I didn't learn my lesson and tried again on the mast afew days ago with the same results. Does anyone have a recommendation for a more reliable wire wheel for a dremel?