Use the largest size you have room for. I used their large clear model for access to our head plumbing, on the front of the molded counter where the sink is located.

Last edited:

EricsonYachts.org has opened the season for raising funds to support the expenses of the site. If you would like to participate, please see the link below for additional information.

Thanks so much for your continued support of EricsonYachts.org!

Since I didn't cut an access hatch in, I had to get a little creative with how the valve was actually secured. These valves are designed to be installed before the wall is closed in and are usually mounted on a 2x4 between the studs. I had to make a plywood bracket that I could attach the valve to and connect it to the backside of the existing panel. Unfortunately, this is the only picture I have of the bracket before I installed it. its the plywood piece on the table in the lower corner of this pic:

View attachment 51667

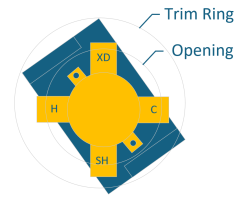

Here's a quick sketch of how it fits in the existing hole:

View attachment 51666

It would be impossible to plumb it up with it in place, so I had to do everything in a specific order:

- Run all electrical wires and conduits while the valve was out (hopefully this will be the last time I access this area for a long time)

- place the plywood bracket in the compartment, but don't secure it yet.

- install the shower head hose through the lower hole and out the access hole

- Plumb the valve body (H - hot, C - cold, XC is a cap, and SH - shower head hose). leave all the plumbing long.

- (Optional step - connect the long hoses to the boats plumbing and pressure test the assembly)

- feed the plumbed assembly through the hole and position

- secure the plywood bracket to the back of the panel using screws from the front of the panel

- secure the valve to the bracket

- complete the final connections under the sink

- install the trim ring, valve, and handle.

I just got back from the boat and saw the connections you referenced beneath the sink. My water tubing for the shower shares a pretty snug hull with an overboard sewage discharge line. I think getting new lines through that hole might be very challenging. An approach I'm considering is along these lines: Detach the existing PB piping from the sink, remove the shower valve from the existing opening, pull it a few inches out using the slack from the detached lines, plumb new fittings and a short piece of PEX connected to the PB. Push everything back in and reconnect the sink lines. This might be the cleanest approach. Do you see anything I'm missing?Yes, there's a hot and cold line from the engine compartment. each hits a T that's directly threaded on the faucet. The third leg of the T runs to the shower mixing valve. I cut that line to splice in the new PEX plumbing. Polybutylene is flexible, so it easily pulled down below the sink. When I was done, I tucked everything back up behind the sink and secured with plastic hose clips.

I ran into the same issue you mentioned with the PB to PEX shark bites which is why I ended up using the Flair-it connectors I linked in an earlier post.

This is great input, thanks so much for the help. It looks like you went from 3/8 PB to 1/2 inch pex, correct? I think cutting the line and splicing in a fairly open spot would be easier than messing with the entire sink valves. I'll scan back up this thread and look at the fittings you used. I'm also considering using 3/8 pex because it will be easier to twist around etc. I don't know if we will ever really use the shower, so pressure is not that imprortant.The passage through the aft head bulkhead between the locker where the holding tank is and the cabinet is tight, but you shouldn't have to replace that line unless you want to replace everything back to the engine compartment. The passage from the sink to the shower mixing valve is pretty easy and is only shared with the water tank vent line.

View attachment 51669

The waste overboard line should be a 1.5" line connected to a thru hull directly below the sink and shouldn't be in the way of any of your work.

If you don't intend to replace the sink connection, I would leave them alone. The PB Fittings are delicate and you should avoid tinkering with them unless you intend to replace them. Just cut the line after the tees like this:

View attachment 51671

He's the tees to the sink

View attachment 51668

Nick, it looks like a size difference between the PB and PEX tubing. My PB tubing matches 3/8" PEX tubing. Did you use 1/2" PEX for your new tubing?

I really like the flexibility of the 3/8 tubing for easy routing and all that. I don't see a need for high water flow on this vessel. I'm really hoping we can close the deal and be the owners soon. We live in what I believe is the perfect place for cruising sailing/island hopping.Way back when I replaced 90% of the factory Qest tubing, I went with 3/8" flexible tubing, I reformatted the whole system for barbed fittings with clamps. I knew that 1/2" tubing would provide a bit more flow, but the available tubing -at that time- from the local industrial hose shop was 3/8. This has worked great for over 20 years. It is a rather garish yellow color with fiber reinforcement and rated for 100++ psi and certified safe for humans -- it's used commonly for air hose for positive pressure masks for workers in hazardous spaces. It was a lot cheaper than the usual marine water system hose, but also has an FDA approved liner,

The guys at the shop kinda steered me away from the much-more expensive water system hose. They do a lot of business with the boating community for bilge and exhaust hoses, also... and carry a lot of ss and brass or bronze fittings to adapt lots of things to lots of other things.

Speaking of hiding your head in shame... not much room for that on a small sailboat!