Chris Mc.

Member III

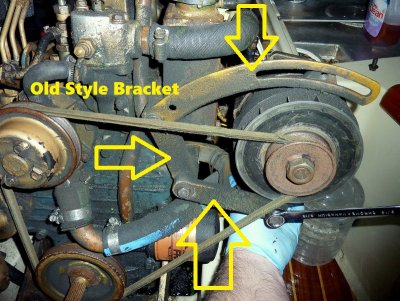

I’ve read with interest the past forums concerning replacing the stock overhead alternator bracket with a lower bracket on the Universal engines. Concerning my engine, from what I can muster, it is different than what I see previously discussed. Is my assertion correct? From my perspective it appears to be a good solid mount.

Thanks.

Thanks.