Bad news, looking for advice.

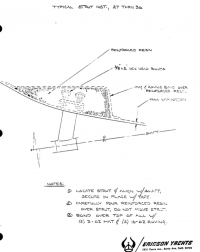

I have an E 27 with Atomic 4 inboard power. Last week a diver cleaning my hull informed me that my prop strut was loose and wiggling by hand. I just had the boat hauled to investigate to find that the fairing over the bracket is missing and the strut can be manipulated. Further it appeared that there weren’t any bolts holding it in place, like someone had simply faired it in. Last time the boat was out of the water this wasn’t seen. Early in the summer I wrapped a dockline. Motoring doesn’t seem any different before or after that event. I have always had enough vibration while motoring at any kind of speed to rattle the lazurette lid. I don’t see evidence that I am leaking from under the gas tank where the prop shaft would bolt through the hull, but I do leak a little bit at the packing gland enough that my bilge pump pumps out a little bit (maybe a pint or two) somewhat regularly.

I am waiting for an estimate from the boatyard and have been warned that it will likely be expensive. I’m expecting multi thousands of dollars and wonder what options I should consider.

Restore with the existing Atomic 4

Repower with diesel

Repower with outboard

Sell/donate/scrap boat and buy a healthier boat because the cost isn’t worth it for a 73 E 27

I have an E 27 with Atomic 4 inboard power. Last week a diver cleaning my hull informed me that my prop strut was loose and wiggling by hand. I just had the boat hauled to investigate to find that the fairing over the bracket is missing and the strut can be manipulated. Further it appeared that there weren’t any bolts holding it in place, like someone had simply faired it in. Last time the boat was out of the water this wasn’t seen. Early in the summer I wrapped a dockline. Motoring doesn’t seem any different before or after that event. I have always had enough vibration while motoring at any kind of speed to rattle the lazurette lid. I don’t see evidence that I am leaking from under the gas tank where the prop shaft would bolt through the hull, but I do leak a little bit at the packing gland enough that my bilge pump pumps out a little bit (maybe a pint or two) somewhat regularly.

I am waiting for an estimate from the boatyard and have been warned that it will likely be expensive. I’m expecting multi thousands of dollars and wonder what options I should consider.

Restore with the existing Atomic 4

Repower with diesel

Repower with outboard

Sell/donate/scrap boat and buy a healthier boat because the cost isn’t worth it for a 73 E 27