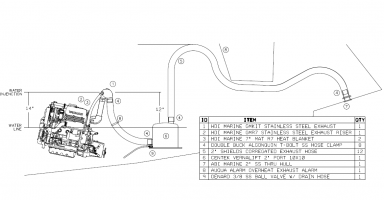

Segue has a new exhaust system! Everything from the exhaust manifold to the back of the boat has been replaced. Even the plywood the muffler sits on was replaced. I went with Shield corrugated exhaust hose to help with the bends below the cockpit sole, on to the thru hull, and to the outlet of the muffler. I also added a 7” riser from HDI marine before the mixing elbow to get a full 12” drop from the water injection point to the top of the muffler. An added bonus was getting 14” from the injection point to the water line which removes the need for a vented loop. The riser caused a little issue with the water injection hose since the port on the back of the heat exchanger is a little larger than ¾ but the nipple on the mixing elbow is 5/8. Yanmar sells a special hose for this, but it’s too short to account for the riser. I tried to heat some 5/8 heater hose to fit around the ¾” port, but it didn’t go as well as I hoped. In the end, I went with a barbed splice to add a 6” piece of 5/8” hose to the original Yanmar hose.

I also added a valve to the front of the muffler to make draining easier as the drain bolt that comes with the muffler is in an awkward spot. I used the old muffler to test drilling and tapping NPT threads. This saved me from buying a third muffler as I realized the wall wasn’t thick enough and I needed to add a piece of G10 to provide additional material for the treads to bite.

Enlarging the thru hull turned to be much easier than I had anticipated. I was worried about blowing out the fiberglass, gelcoat, or Awlgrip paint with the hole saw. However, the backing plate I epoxied to the hull provided a good guide for the hole saw and the old thru hull flange kept the outside intact. I used butyl tape to temporarily seal the thru hull while its in the water. When I have the boat on the hard and have better access, I’ll reseal it with something else.

The only thing left to do is add the exhaust temp sensor which will give me some piece of mind that I won’t burn up all this work.

I also added a valve to the front of the muffler to make draining easier as the drain bolt that comes with the muffler is in an awkward spot. I used the old muffler to test drilling and tapping NPT threads. This saved me from buying a third muffler as I realized the wall wasn’t thick enough and I needed to add a piece of G10 to provide additional material for the treads to bite.

Enlarging the thru hull turned to be much easier than I had anticipated. I was worried about blowing out the fiberglass, gelcoat, or Awlgrip paint with the hole saw. However, the backing plate I epoxied to the hull provided a good guide for the hole saw and the old thru hull flange kept the outside intact. I used butyl tape to temporarily seal the thru hull while its in the water. When I have the boat on the hard and have better access, I’ll reseal it with something else.

The only thing left to do is add the exhaust temp sensor which will give me some piece of mind that I won’t burn up all this work.