> Before you removed that part of the sole, was it all one piece, sealed?

No. Separate pieces for galley, nav station, etc. 5 sections total. But the moisture had realistically turn them into one

.

I agree with Tom about not trying to keep the water out of those areas. Water will find it's way there. I just want

all the water to find it's way back to the bilge pump.

Ericson had no less than 25 SS screws holding down a roughly 2' x 2' section of sole in the galley. My daughter, who was helping me remove the sole, thought whoever built the boat was crazy or really drunk at the time.

I also want a very "removable" sole. I value functionality above looks as any sailor should.

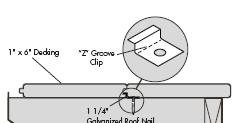

If Any of you saw my other post about a plastic lumber sole, I'm still looking into it. The plastic flooring is looking better to me ever day. Our boats are made out of plastic anyway, not wood, so why not a plastic sole. Easy to install 3/4" x 6" tongue and grove planks with bronze square head screws - I'd be all set. I'd make sure to make separate sections as Loren suggested.

Jason