simdim

Member II

Folks,

Hope everyone had wonderful holidays!

Though temperature outside is balmy 6F it is time to think about refitting for the new season. I wonder what you would say about installing Organizer Plates ( http://www.dwyermast.com/items.asp?...milyID=19&familyName=Halyard+Organizer+Plates )under the mast step as opposed to installing mast base blocks that are bolted to the cabin top. How big of a deal is it to remove ( and reinstall) a mast step (i am storing with mast down this winter). I really want to move all lines aft with minimum trough cabin drilling...

Hope everyone had wonderful holidays!

Though temperature outside is balmy 6F it is time to think about refitting for the new season. I wonder what you would say about installing Organizer Plates ( http://www.dwyermast.com/items.asp?...milyID=19&familyName=Halyard+Organizer+Plates )under the mast step as opposed to installing mast base blocks that are bolted to the cabin top. How big of a deal is it to remove ( and reinstall) a mast step (i am storing with mast down this winter). I really want to move all lines aft with minimum trough cabin drilling...

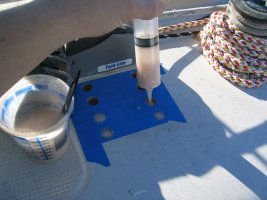

). and have a question - what was the reason to drill all way trough? I was planning to just to drill 5/8" holes from the top, remove the core and fill the void with epoxy - one of my goals is to reduce the cosmetic damage to the inside of the cabin.

). and have a question - what was the reason to drill all way trough? I was planning to just to drill 5/8" holes from the top, remove the core and fill the void with epoxy - one of my goals is to reduce the cosmetic damage to the inside of the cabin.