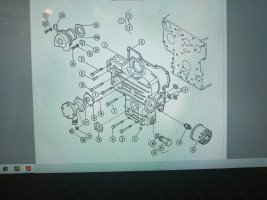

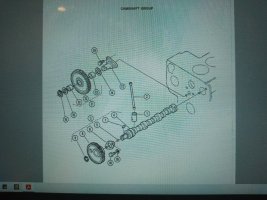

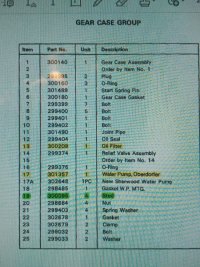

So I was going to replace my Oberdorfer pump on my M25 due to noticing some leakage of salt water underneath it. Upon removing it I find something fairly concerning - oil dripping from the back of the raw water pump, and perhaps worse block corrosion than anticipated.

so, what am I looking at? That bottom post came out as I was unscrewing it, and that whole corner looks like it’s missing a chunk or something. Are those posts standard parts somewhere I could buy, or universal specific? The one that came out had some stripped threads so I’d like to replace it.

and... oil where it shouldn’t be is scary. I haven’t found any evidence of water in oil but perhaps my smoke issues have been oil in water, albeit very slight. Any guidance appreciated.

so, what am I looking at? That bottom post came out as I was unscrewing it, and that whole corner looks like it’s missing a chunk or something. Are those posts standard parts somewhere I could buy, or universal specific? The one that came out had some stripped threads so I’d like to replace it.

and... oil where it shouldn’t be is scary. I haven’t found any evidence of water in oil but perhaps my smoke issues have been oil in water, albeit very slight. Any guidance appreciated.