John McCarroll

Junior Member

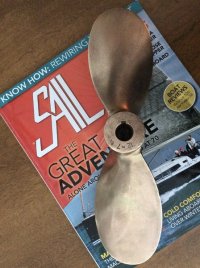

This week I am removing my prop to clean, buff and have it inspected. I have used the search function here and on Youtube but have not seen this process documented. If anyone has an link or advice please share. The prop is on our Ericson 27 "Tamaki". Thanks! JM

Part 2: removed the cotter pin and lock nut, I can see it is a taper fit on shaft so I am going to borrow the prop puller and remove prop.

Part 2: removed the cotter pin and lock nut, I can see it is a taper fit on shaft so I am going to borrow the prop puller and remove prop.

Last edited: