Deborah,

I used to have a squishy sole in that same area. The sole was so easy to lift up in that area that it tricked me into removing the whole section. Unfortunately, the further I got away from that area, the less the adhesive had loosened, and the harder it became to remove the sole.

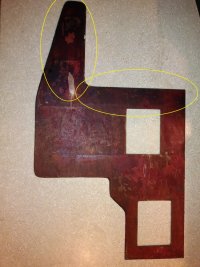

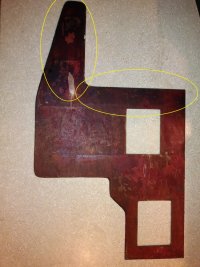

When I finally removed it, it looked like this underneath:

I saw no way for water to come in from below (from the TAFG) in this area. That little plywood cover over the TAFG-well (shown in Filkee's picture) was sealed in so firmly with heavy-duty caulk that I had to destroy it to remove it.

My theory is that any water from the galley area flows along the seam where the sole and TAFG meet, looking for a place to pool where the sole is not well-adhered. The darkened areas in my photo show the places that were exposed to water, even though I only noticed under that aft-most tab, where I could see the water squeezing out.

About the only other thing that "drains" into this area is, possibly, fluids from the engine.

I've had water running down that little track to port of the engine after changing the heat exchanger zinc. Also, diesel spills after changing fuel filters. I believe this is why my sole was so loose in this area--the wood had a strong diesel smell when I removed it. That's probably what softened up the glue.