A nearby Thread is discussing SS stern rails and dinghy davits and the subject of custom SS work crept in, and rather than subvert that thread any further...

It seemed best to start a new one on custom SS work, like a "fix" for bent stanchions.

Personal Rant: It has bothered me for years that one must, on almost all boats, caution the crew and guests NOT to lean or pull on the stanchions too hard or they will bend. The illogic of this has not been lost on visitors that give back a puzzled look when warned not to lean or pull on those SS stanchions too much to avoid harming them. This is part of explaining that the pipes in question are part of something called, oddly enough, the Life Lines!

Docking is another perilous time, when all and sundry must be warned to grab the boat only (!!) by the rail or stanchion base, to avoid hurting the stanchions. (Considering the weight of the boat, this at least makes a lot more sense!)

As part of this spring's rail/stanchion/wire upgrade, we went to a local SS fabricator and worked out a design for braces for the two mid stanchions, and a two-way brace for the aft one on each side where the gate is. On the Olson, unlike most all of the later Ericsons, there was no stock gate brace.

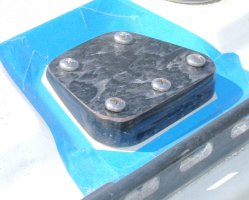

We now have epoxy glass plates under *all* bases, pulpits included. I spent a lot of time contorted into bow and stern and inside cabinets while applying epoxy and "FR4/G10" plate pieces under all bases. All were then drilled out and longer quarter-20 bolts put back in. The original full size SS backing plates were re-used.

In our case, four out of the eight stanchions were bent to some degree. All were straightened and mirror polished. Peculiar to the Olson 34, they leaned out about 8 degrees from vertical, and we also had eight black delrin wedges machined for each base to almost-but-not-quite re-orient them more upright.

Of course as soon as we got the stanchions back we realized that the old pulpits now looked like cr_p, so off they came for polishing and some straightening (of the bow pulpit, bent by the first owner), and making some old wiring holes in the stern rails disappear.

Here is a look at the new braces. More pictures can be added if there is any interest. Note that the attachment bolts to the toe rail are insulated with nylon washers to prevent electrolysis.

Best,

Loren

It seemed best to start a new one on custom SS work, like a "fix" for bent stanchions.

Personal Rant: It has bothered me for years that one must, on almost all boats, caution the crew and guests NOT to lean or pull on the stanchions too hard or they will bend. The illogic of this has not been lost on visitors that give back a puzzled look when warned not to lean or pull on those SS stanchions too much to avoid harming them. This is part of explaining that the pipes in question are part of something called, oddly enough, the Life Lines!

Docking is another perilous time, when all and sundry must be warned to grab the boat only (!!) by the rail or stanchion base, to avoid hurting the stanchions. (Considering the weight of the boat, this at least makes a lot more sense!)

As part of this spring's rail/stanchion/wire upgrade, we went to a local SS fabricator and worked out a design for braces for the two mid stanchions, and a two-way brace for the aft one on each side where the gate is. On the Olson, unlike most all of the later Ericsons, there was no stock gate brace.

We now have epoxy glass plates under *all* bases, pulpits included. I spent a lot of time contorted into bow and stern and inside cabinets while applying epoxy and "FR4/G10" plate pieces under all bases. All were then drilled out and longer quarter-20 bolts put back in. The original full size SS backing plates were re-used.

In our case, four out of the eight stanchions were bent to some degree. All were straightened and mirror polished. Peculiar to the Olson 34, they leaned out about 8 degrees from vertical, and we also had eight black delrin wedges machined for each base to almost-but-not-quite re-orient them more upright.

Of course as soon as we got the stanchions back we realized that the old pulpits now looked like cr_p, so off they came for polishing and some straightening (of the bow pulpit, bent by the first owner), and making some old wiring holes in the stern rails disappear.

Here is a look at the new braces. More pictures can be added if there is any interest. Note that the attachment bolts to the toe rail are insulated with nylon washers to prevent electrolysis.

Best,

Loren

Attachments

Last edited: