Vtonian

E38 - Vashon

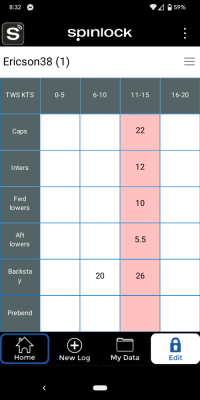

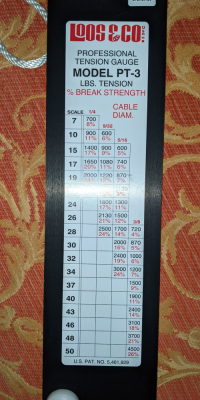

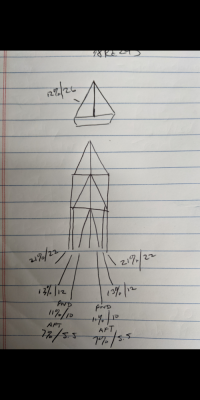

Ignoring that there's possibly/probably an underlying problem that needs to be solved, I'm learning to tune my E38 rigging, which was pretty loose as bought. Going with a blend of the Ericson docs, Loos gauge suggestions, a consensus of rig tuning YouTubes, and tempered with consideration for age and a careful visual inspection, I'm at a point where there appears to be a slight "S" in the mast, even though the shrouds are already slightly tensioned to counter it.

If I take the S completely out, the tension will be significantly more unbalanced. If I balance the shroud tension, the S will be more pronounced. I feel like I’m at a ‘good’ compromise set/tune, but I have never seen anyone suggest to compromise rig tune.

The PO put a new boot on the mast, and I don't know if the E38 (1985) has adjustable wedges or has a fixed position collar, so I don't want to start dismantling that until I know if there's anything to adjust there. It’s my first thought though, he wasn’t a sailor so maybe ignored/hid a correctable problem there.

FWIW, I started with the more commonly recommended procedure of loosening all shrouds first, then setting the masthead for center, rake and tension, then working from mids, down. Oddly, Brian Toss (only very briefly) mentions working lowers, up, and I’m contemplating starting over trying that.

Obvz, a professional should be consulted but it’s a beautiful day, I’m enjoying the process and keeping this side of harm.

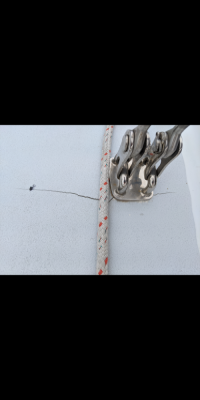

Side note: the port chain plate, the one that angles forward to the head bulkhead after penetrating the deck, has a little crazing and lifting around it, but the deck taps out sounding solid. I’m hoping it’s a common ‘feature’ of the design that just needs maintenance and not a bug that needs repairs, although I do intend to rebed everything ASAP.

Input and comments appreciated...

If I take the S completely out, the tension will be significantly more unbalanced. If I balance the shroud tension, the S will be more pronounced. I feel like I’m at a ‘good’ compromise set/tune, but I have never seen anyone suggest to compromise rig tune.

The PO put a new boot on the mast, and I don't know if the E38 (1985) has adjustable wedges or has a fixed position collar, so I don't want to start dismantling that until I know if there's anything to adjust there. It’s my first thought though, he wasn’t a sailor so maybe ignored/hid a correctable problem there.

FWIW, I started with the more commonly recommended procedure of loosening all shrouds first, then setting the masthead for center, rake and tension, then working from mids, down. Oddly, Brian Toss (only very briefly) mentions working lowers, up, and I’m contemplating starting over trying that.

Obvz, a professional should be consulted but it’s a beautiful day, I’m enjoying the process and keeping this side of harm.

Side note: the port chain plate, the one that angles forward to the head bulkhead after penetrating the deck, has a little crazing and lifting around it, but the deck taps out sounding solid. I’m hoping it’s a common ‘feature’ of the design that just needs maintenance and not a bug that needs repairs, although I do intend to rebed everything ASAP.

Input and comments appreciated...