A few words first…

When I read any “How To” article on-line I’m always cautious about the information especially if it’s from a “non-professional”…..like me. I’m just a photographer who really likes sailing and repairing / upgrading his boat. So I humbly off this story about how I did some work on my boat and not as a definite “how to” guide because I make mistakes and there maybe a few in the following paragraphs that you’ll find or at least have an opinion on.

Why The Upgrade?

Anything mechanical eventually requires repair, replacement or upgrade and our “good olde boats” are no exception. With that in mind I decided to replace the original Schaefer mainsheet traveler on Vesper our E32-3, hull #722 built in 1987. The 2:1 purchase combined with the old traveler design and age of the main sheet car / track added a lot of resistance so pulling the boom up to windward often took a lot of muscle and sometimes was impossible if the wind was really up. When using old and outdated equipment that requires extra ordinary physical effort to use, and in doing so may lead to damage or injury, an upgrade is definitely in order and a good investment.

After some research I narrowed it down to two brands, Garhauer and Harken. Both had the capability of giving me a 4:1 purchase making it easier to move the main sheet car under load. The other requirement was that the traveler track had to be bent to match the curvature of the old Schaefer track, and in turn the profile of the sea hood and the locations of the two existing Schaefer cabin top traveler brackets that I intended to keep. I first called Garhauer to inquire about getting the track bent and was told that they no longer offer that service even though it was listed on their web site as a something they do for their customers. (WHAT?!) Also, I got got a bad feeling with the tone of the tech person I talked to because he sounded as if my inquiry was too much of a bother for him. Red flags all around!

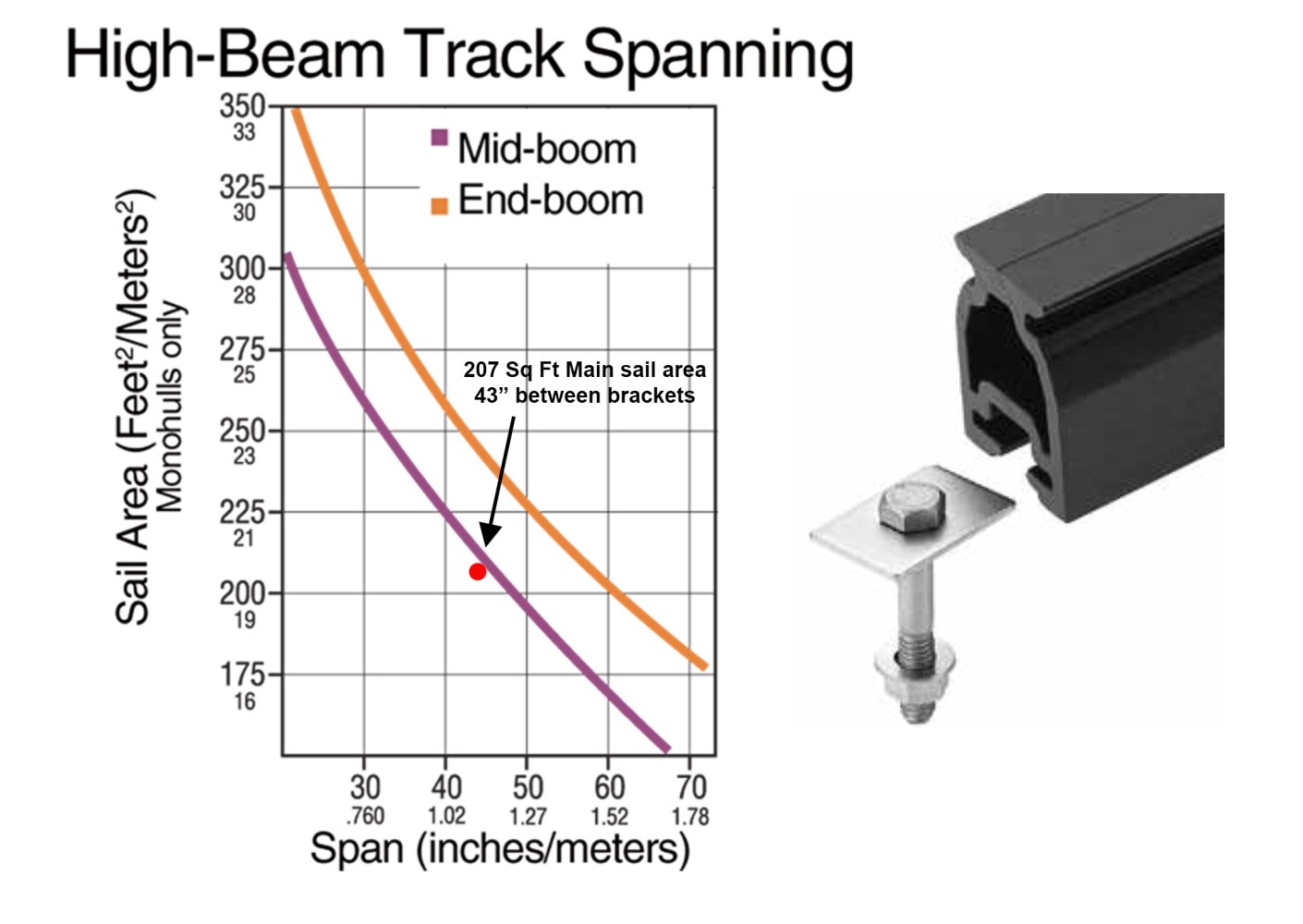

Harken Marine on the other hand was very helpful right from the start giving good support via email or phone plus I was even able to talk to a Harken representative in person at the Annapolis Sailboat Show who helped me in selecting the right traveler, car and control ends for my E32-3. Bending the track to match the existing Schaefer curvature wasn’t a problem either and they were happy to do it too. The track that Harken recommended for my boat was their R27HB, Mid-range, “High-Beam” along with the #1655 Traveler kit to obtain a 4:1 purchase. The “beefy” 27mm wide track is designed for spanning a cabin top. On their web site you can find a chart for this track that shows the maximum unsupported distance depending on sail area, span and if the main sheet attachment is mid or end-boom. The Ericson 32-3 is mid-boom and the maximum unsupported span distance and main sail area of 207 square feet falls within the range recommend which meant that the only attachments really needed to be at the existing main sheet traveler brackets that I planned on using. But since the span distance was close to the recommended maximum I decided that also bolting it to the sea hood would help in reducing any flex in the track and take some of the strain off the end brackets.

Spanning Chart / "High-Beam" Track with Internal Slide

The Harken R27HB track is designed for a re-fit. Instead of having to match and drill the attachment holes that may exist on the boat, the track has a “groove” in the bottom of the profile that allows for “internal slide mounts” (supplied with the track) that accept 1/4” diameter hex head bolts (not supplied) so that the fasteners can slide along the bottom of the track and match any bolt location. The negative side of that feature is that the head of the bolt is hidden and can’t be used to tighten it down. That can only be done with the nut at the other end and the access to that is restricted on the E32-3, but I’m getting a bit ahead of myself here. Not to worry, I did come up with a solution.

The "Old" Schaefer Main Sheet Traveler

The old Schaefer track was bolted down at twelve locations. Two bolts through each of the two cabin top brackets at the ends of the traveler with open access to the nuts below, and eight through the traveler that went into the sea hood where they were threaded into a backing plate that's glassed into the hood. If you’ve ever tried to remove something that has been attached to a boat for a long time you’ll know that it’s doesn’t always go as planned. Three out of the eight 1/4” diameter flat head bolts holding the old track to the sea hood were seized and my many attempts simply destroyed the Phillips heads on the bolts. The only option was to drill the flat heads out and that required about an hour with copious amounts of oil to keep the slow speed drill bit from overheating.

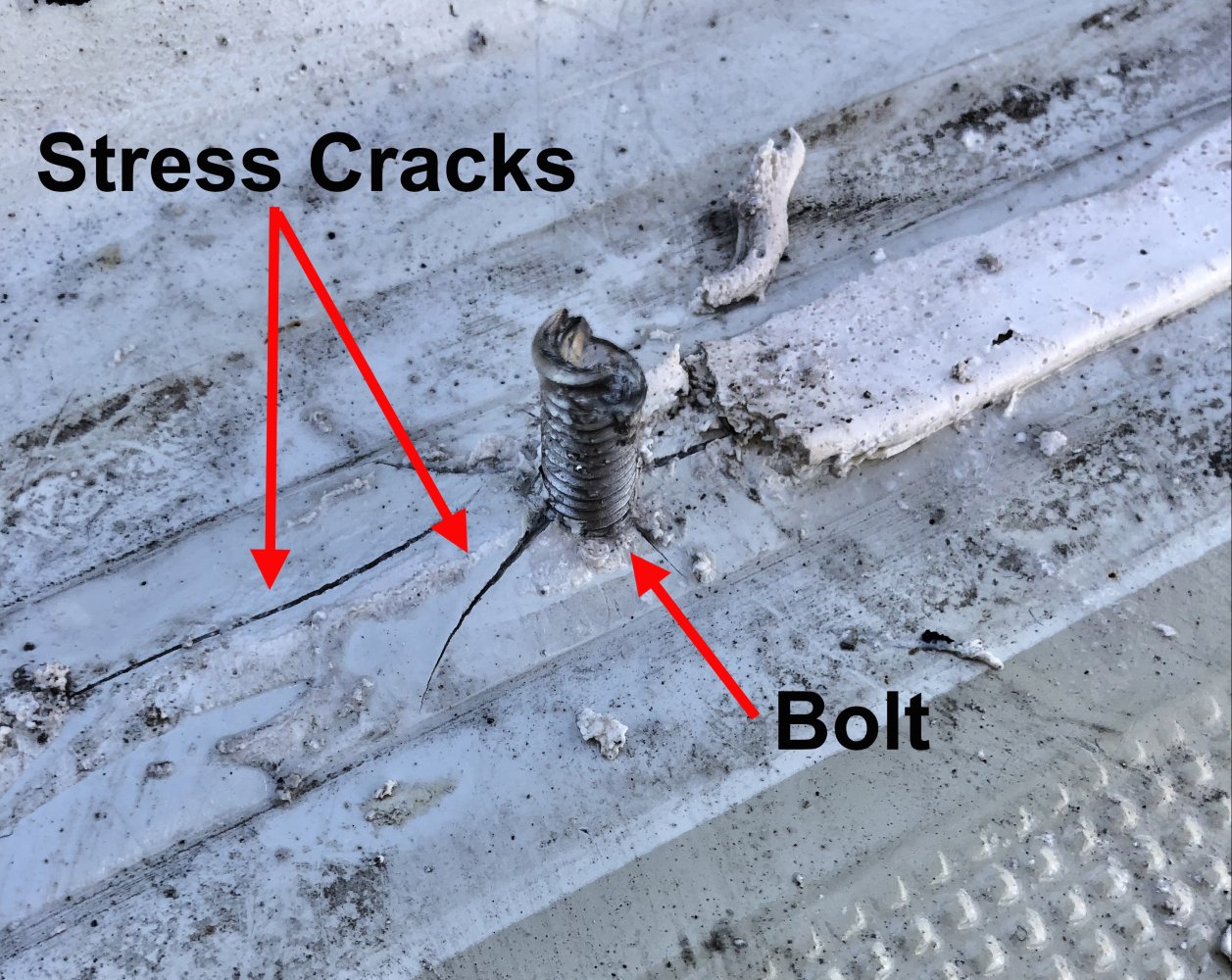

One of the stubborn former flat head bolts that required having its head drill off. The remaining part was cut flush to the top of the sea hood. Notice the stress cracks around the bolt probably from forces exerted by the loads on the traveler.

After the track was freed, this left three mangled threaded studs protruding from the sea hood which were dispatched by cutting them flush using a Dremel tool. I then removed some very old and hard original caulking using Marine Formula and a flat metal scraper. The “de-bonder” is sold in a spray can that I purchased on Amazon. (https://www.amazon.com/gp/product/B07CSYP3LH/ref=ppx_yo_dt_b_search_asin_image?ie=UTF8&psc=1) Next I removed the wood trim, which is attached to the back edge of the sea hood by four flat head wood screws that are under teak plugs. To remove a teak plug, select a drill bit smaller than its diameter and carefully drill down into its center which should lift the plug right out when you reach the top of the flat head screw. You’ll often get a clean extraction but sometimes parts of the plug break off and remain in the hole which you can remove with a pick or small flat screw driver.

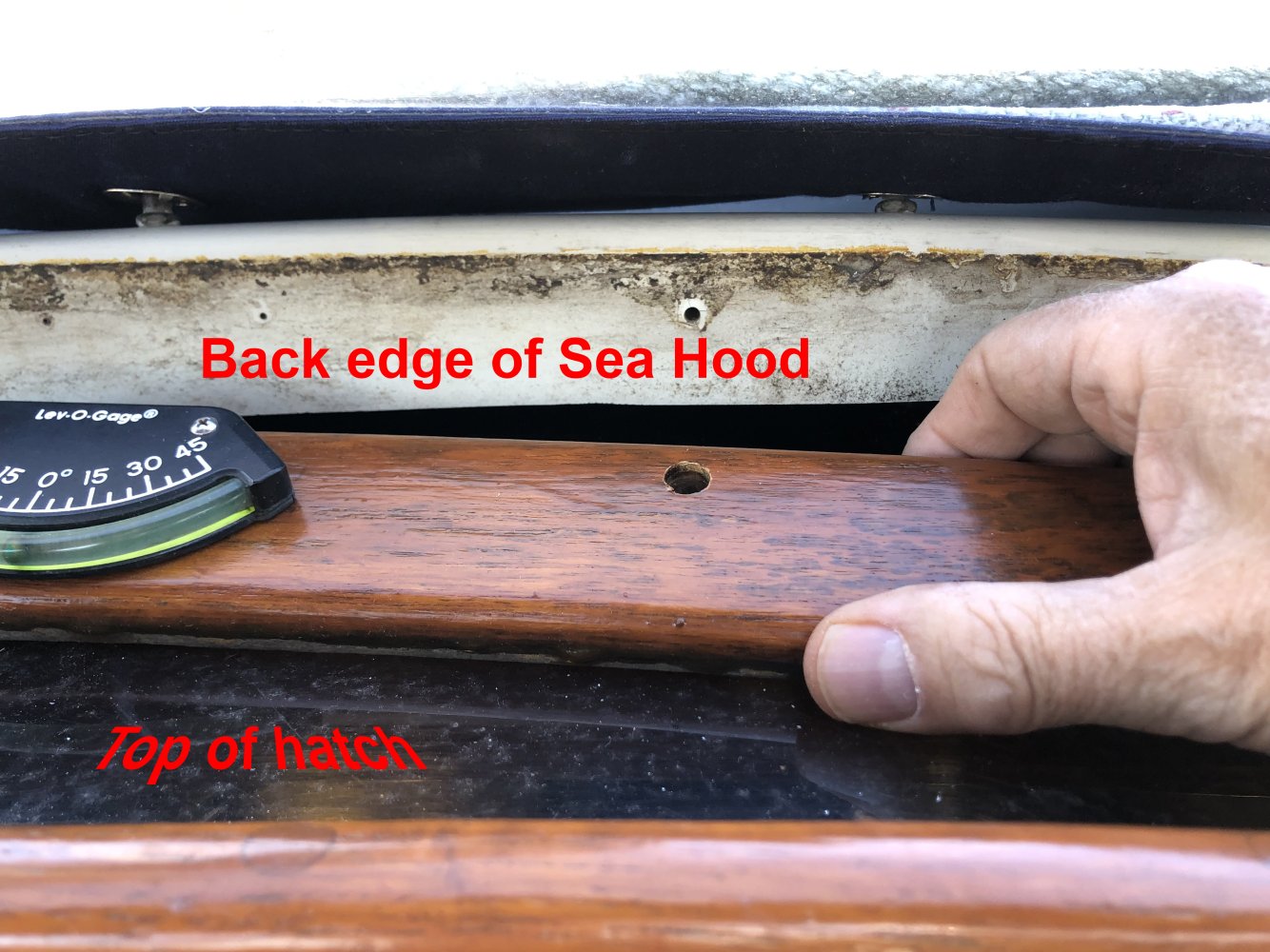

Using an inspection mirror I could see the threaded hole (red arrow in photo below) where a former traveler bolt came through the glassed in backing plate. The obvious problem was the restrictive space between the edge of the sea hood and the top of the sliding hatch. Removing the wood trim helped. Removing the hatch however would require removing the sea hood which I didn’t want to do. Sliding on a large fender washer and threading on a nut by hand was going to be almost impossible.....or so I thought.

Inspection mirror between the edge of the hood and top of the hatch shows the threaded bolt hole here out of focus because of the limitations of my iPhone.

With the old Schaefer track free I shipped it to Harken as a guide for bending the R27HB. When both tracks were returned the new Harken was very close to the same curvature of the old Schaefer, but not quite exact. Laying them side by side I determined that the Harken track was about 1/4” off at one end but I figured I’d be able to adjust for any deviations with some flat washers. I imagine that bending a new track to “exactly” match isn’t easy and some deviation was probably expected. Back on the boat, using a 5/16” bit, I drilled out the three sea hood threaded bolt hole locations, one at the center of the hood and two more at the port and starboard sides. Then I laid down a strip of butyl tape over the “foot print” area for the new track, punching a hole through the tape at each of the three holes I’d be using but being sure that the tape surrounded the holes.

Harken supplies “Internal Slide Mounts” that you slip a 1/4” hex head bolt through and then you slide the bolt/slide assembled into the slot at the bottom of the track and move it to the desired location along the track. They don't supply the bolts because of the variety of bolt lengths required for each boat application. All of the bolts in the track, for the hood and both brackets, need to be slipped into their holes at the same time and it’s something that takes a bit of practice. I did the whole process about six times, making adjustments with washers for the track deviation till I got it right. After the the bolts are in place and the track is centered up with the sea hood you bolt it down tight. This is easy at the cabin top brackets on the ends of the track because the nuts are accessible, but where the three bolts went though the sea hood the ends were not even visible because of the limited space between the bottom of the sea hood and top of the sliding hatch. So, how to slip on a large fender washer over a bolt end you can’t even see, keeping it from falling off until you can thread on a locking nut? There just wasn’t enough room for more than one of my fingers. This is where a little butyl and blue tape does the trick.

I stuck some small bits of butyl tape on the washer which allowed it to stick to the bottom of the sea hood after slipping it over the bolt end. To thread on the 1/4" lock nut I put a small strip of blue tape over one side of a 7/16 wrench so the nut wouldn't slip though. Then I carefully stuck the wrench under the sea hood and using my sense of touch, rather than sight, I maneuvered the nut to the bolt end and gently started a thread or two. Gradually I was able to tighten each nut down and it was actually easier then I thought it would be although it did take more time to do than usual. Beats removing the sea hood and sliding hatch!

Tightening the un-seen nuts.

New Harken Track Bolted In Place with "adjustment tool" nearby.

As I mentioned, when the original Schaefer track came back with Harken track, I determined that the bend was off about 1/4” at one end. This ended up being at the starboard side of the track. Maybe I could have tried to force that end down to the bracket by tightening the bracket bolts but I didn’t think I could get the track to bend a 1/4” in just a 10 to 12 inch section. So I added four flat washers at each bolt between the bracket and the bottom of the track to take up the space. After all the bolts were tightened the track was rock solid. I also ordered Harken “trim caps” (#1622) that snap into the ends of the track. Then I replaced the wood trim back over the sea hood edge.

Starboard mounting bracket with washer “spacers” in place.

The next step was to install the Harken Midrange Traveler Kit , (#1655) which consists of a port/starboard control ends and a car. First you need to select the best position for the end controls that have the cam cleats. This will vary from boat to boat so there is no “standard” position. Mine was determined by the architecture of the dodger and where the old Schaefer control lines came through it. I basically put the Harken control ends in the same spot on the track. Slide one of the control ends onto the track, position it and then mark the center of the hole you will drill though the track. Bolt in place and then slide the car on, that has the control sheaves, onto the track. Finally position the second car like the first, drill and bolt through the track.

The next step was to install the Harken Midrange Traveler Kit , (#1655) which consists of a port/starboard control ends and a car. First you need to select the best position for the end controls that have the cam cleats. This will vary from boat to boat so there is no “standard” position. Mine was determined by the architecture of the dodger and where the old Schaefer control lines came through it. I basically put the Harken control ends in the same spot on the track. Slide one of the control ends onto the track, position it and then mark the center of the hole you will drill though the track. Bolt in place and then slide the car on, that has the control sheaves, onto the track. Finally position the second car like the first, drill and bolt through the track.

The final step is to add the control lines and it depends on the length of the traveler and the purchase. For a 4:1 purchase with the #1655 kit I installed Harken provides this formula: Track Length x 4 plus 3 feet and they specify 8 MM line. So I went to my local West Marine rigging department with formula in hand and they supplied two control lines with an eye on one end and the bitter end whipped. Back at the boat I removed the hex head bolts that held down the sheave assembly on the control end, being careful not to lose the ball bearing assembly mounted in the sheaves when I lifted it, and looped the eye of the control line over the “deadend horn”. Then I re-tightened the sheave assembly back into the control end.

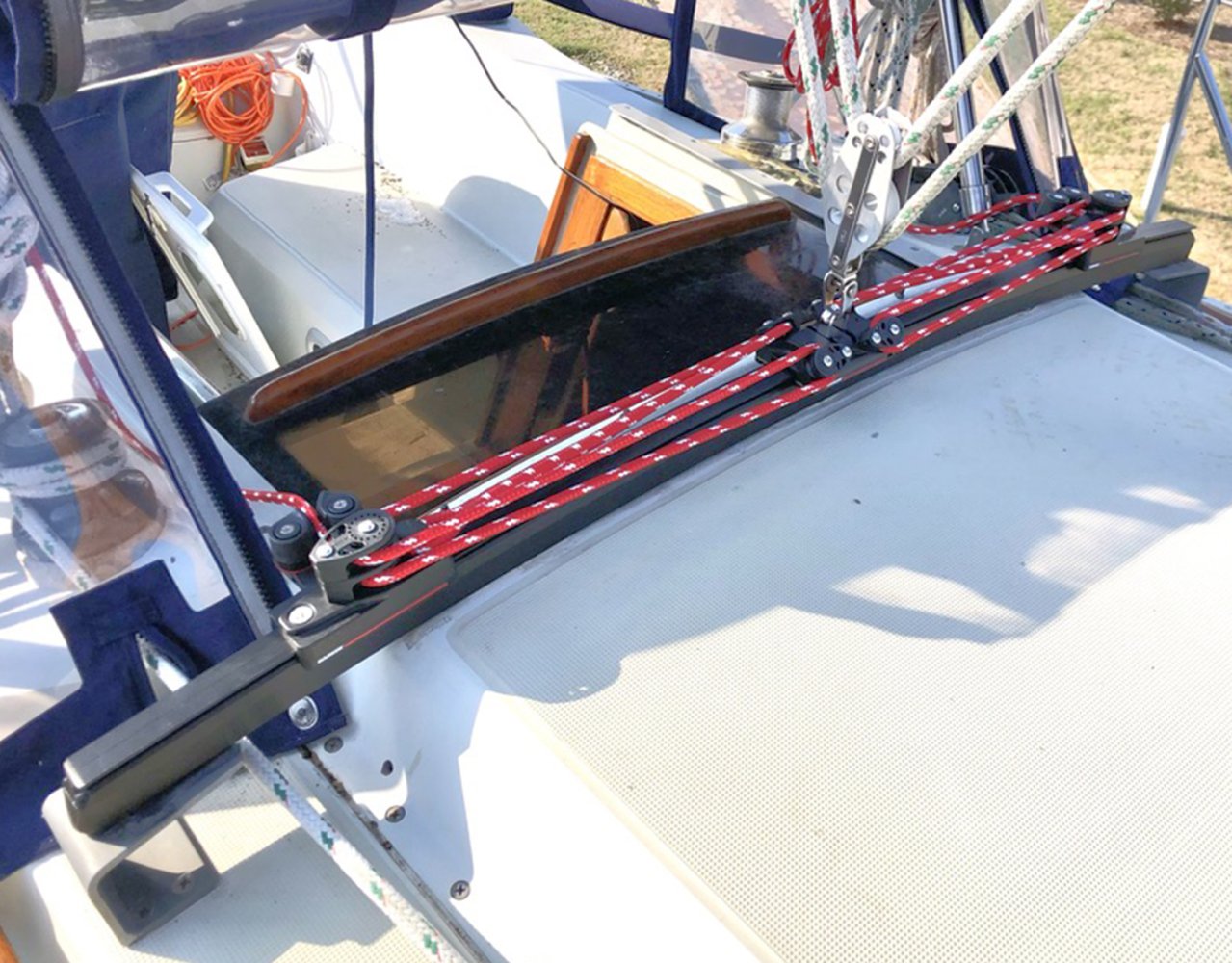

Harken provided a clear guide on how to reeve the control lines though the sheave and then finally though the cam cleat to get a 4:1 purchase. Unfortunately for me, I won’t be able to experience the benefits of the traveler upgrade because the boat was hauled out for the winter and put “on the hard” for scheduled maintenance in the spring, but I'm sure the upgrade will prove to be a great improvement.

Completed Traveler Upgrade

When I read any “How To” article on-line I’m always cautious about the information especially if it’s from a “non-professional”…..like me. I’m just a photographer who really likes sailing and repairing / upgrading his boat. So I humbly off this story about how I did some work on my boat and not as a definite “how to” guide because I make mistakes and there maybe a few in the following paragraphs that you’ll find or at least have an opinion on.

Why The Upgrade?

Anything mechanical eventually requires repair, replacement or upgrade and our “good olde boats” are no exception. With that in mind I decided to replace the original Schaefer mainsheet traveler on Vesper our E32-3, hull #722 built in 1987. The 2:1 purchase combined with the old traveler design and age of the main sheet car / track added a lot of resistance so pulling the boom up to windward often took a lot of muscle and sometimes was impossible if the wind was really up. When using old and outdated equipment that requires extra ordinary physical effort to use, and in doing so may lead to damage or injury, an upgrade is definitely in order and a good investment.

After some research I narrowed it down to two brands, Garhauer and Harken. Both had the capability of giving me a 4:1 purchase making it easier to move the main sheet car under load. The other requirement was that the traveler track had to be bent to match the curvature of the old Schaefer track, and in turn the profile of the sea hood and the locations of the two existing Schaefer cabin top traveler brackets that I intended to keep. I first called Garhauer to inquire about getting the track bent and was told that they no longer offer that service even though it was listed on their web site as a something they do for their customers. (WHAT?!) Also, I got got a bad feeling with the tone of the tech person I talked to because he sounded as if my inquiry was too much of a bother for him. Red flags all around!

Harken Marine on the other hand was very helpful right from the start giving good support via email or phone plus I was even able to talk to a Harken representative in person at the Annapolis Sailboat Show who helped me in selecting the right traveler, car and control ends for my E32-3. Bending the track to match the existing Schaefer curvature wasn’t a problem either and they were happy to do it too. The track that Harken recommended for my boat was their R27HB, Mid-range, “High-Beam” along with the #1655 Traveler kit to obtain a 4:1 purchase. The “beefy” 27mm wide track is designed for spanning a cabin top. On their web site you can find a chart for this track that shows the maximum unsupported distance depending on sail area, span and if the main sheet attachment is mid or end-boom. The Ericson 32-3 is mid-boom and the maximum unsupported span distance and main sail area of 207 square feet falls within the range recommend which meant that the only attachments really needed to be at the existing main sheet traveler brackets that I planned on using. But since the span distance was close to the recommended maximum I decided that also bolting it to the sea hood would help in reducing any flex in the track and take some of the strain off the end brackets.

Spanning Chart / "High-Beam" Track with Internal Slide

The Harken R27HB track is designed for a re-fit. Instead of having to match and drill the attachment holes that may exist on the boat, the track has a “groove” in the bottom of the profile that allows for “internal slide mounts” (supplied with the track) that accept 1/4” diameter hex head bolts (not supplied) so that the fasteners can slide along the bottom of the track and match any bolt location. The negative side of that feature is that the head of the bolt is hidden and can’t be used to tighten it down. That can only be done with the nut at the other end and the access to that is restricted on the E32-3, but I’m getting a bit ahead of myself here. Not to worry, I did come up with a solution.

The "Old" Schaefer Main Sheet Traveler

The old Schaefer track was bolted down at twelve locations. Two bolts through each of the two cabin top brackets at the ends of the traveler with open access to the nuts below, and eight through the traveler that went into the sea hood where they were threaded into a backing plate that's glassed into the hood. If you’ve ever tried to remove something that has been attached to a boat for a long time you’ll know that it’s doesn’t always go as planned. Three out of the eight 1/4” diameter flat head bolts holding the old track to the sea hood were seized and my many attempts simply destroyed the Phillips heads on the bolts. The only option was to drill the flat heads out and that required about an hour with copious amounts of oil to keep the slow speed drill bit from overheating.

One of the stubborn former flat head bolts that required having its head drill off. The remaining part was cut flush to the top of the sea hood. Notice the stress cracks around the bolt probably from forces exerted by the loads on the traveler.

After the track was freed, this left three mangled threaded studs protruding from the sea hood which were dispatched by cutting them flush using a Dremel tool. I then removed some very old and hard original caulking using Marine Formula and a flat metal scraper. The “de-bonder” is sold in a spray can that I purchased on Amazon. (https://www.amazon.com/gp/product/B07CSYP3LH/ref=ppx_yo_dt_b_search_asin_image?ie=UTF8&psc=1) Next I removed the wood trim, which is attached to the back edge of the sea hood by four flat head wood screws that are under teak plugs. To remove a teak plug, select a drill bit smaller than its diameter and carefully drill down into its center which should lift the plug right out when you reach the top of the flat head screw. You’ll often get a clean extraction but sometimes parts of the plug break off and remain in the hole which you can remove with a pick or small flat screw driver.

Using an inspection mirror I could see the threaded hole (red arrow in photo below) where a former traveler bolt came through the glassed in backing plate. The obvious problem was the restrictive space between the edge of the sea hood and the top of the sliding hatch. Removing the wood trim helped. Removing the hatch however would require removing the sea hood which I didn’t want to do. Sliding on a large fender washer and threading on a nut by hand was going to be almost impossible.....or so I thought.

Inspection mirror between the edge of the hood and top of the hatch shows the threaded bolt hole here out of focus because of the limitations of my iPhone.

With the old Schaefer track free I shipped it to Harken as a guide for bending the R27HB. When both tracks were returned the new Harken was very close to the same curvature of the old Schaefer, but not quite exact. Laying them side by side I determined that the Harken track was about 1/4” off at one end but I figured I’d be able to adjust for any deviations with some flat washers. I imagine that bending a new track to “exactly” match isn’t easy and some deviation was probably expected. Back on the boat, using a 5/16” bit, I drilled out the three sea hood threaded bolt hole locations, one at the center of the hood and two more at the port and starboard sides. Then I laid down a strip of butyl tape over the “foot print” area for the new track, punching a hole through the tape at each of the three holes I’d be using but being sure that the tape surrounded the holes.

Harken supplies “Internal Slide Mounts” that you slip a 1/4” hex head bolt through and then you slide the bolt/slide assembled into the slot at the bottom of the track and move it to the desired location along the track. They don't supply the bolts because of the variety of bolt lengths required for each boat application. All of the bolts in the track, for the hood and both brackets, need to be slipped into their holes at the same time and it’s something that takes a bit of practice. I did the whole process about six times, making adjustments with washers for the track deviation till I got it right. After the the bolts are in place and the track is centered up with the sea hood you bolt it down tight. This is easy at the cabin top brackets on the ends of the track because the nuts are accessible, but where the three bolts went though the sea hood the ends were not even visible because of the limited space between the bottom of the sea hood and top of the sliding hatch. So, how to slip on a large fender washer over a bolt end you can’t even see, keeping it from falling off until you can thread on a locking nut? There just wasn’t enough room for more than one of my fingers. This is where a little butyl and blue tape does the trick.

I stuck some small bits of butyl tape on the washer which allowed it to stick to the bottom of the sea hood after slipping it over the bolt end. To thread on the 1/4" lock nut I put a small strip of blue tape over one side of a 7/16 wrench so the nut wouldn't slip though. Then I carefully stuck the wrench under the sea hood and using my sense of touch, rather than sight, I maneuvered the nut to the bolt end and gently started a thread or two. Gradually I was able to tighten each nut down and it was actually easier then I thought it would be although it did take more time to do than usual. Beats removing the sea hood and sliding hatch!

Tightening the un-seen nuts.

New Harken Track Bolted In Place with "adjustment tool" nearby.

As I mentioned, when the original Schaefer track came back with Harken track, I determined that the bend was off about 1/4” at one end. This ended up being at the starboard side of the track. Maybe I could have tried to force that end down to the bracket by tightening the bracket bolts but I didn’t think I could get the track to bend a 1/4” in just a 10 to 12 inch section. So I added four flat washers at each bolt between the bracket and the bottom of the track to take up the space. After all the bolts were tightened the track was rock solid. I also ordered Harken “trim caps” (#1622) that snap into the ends of the track. Then I replaced the wood trim back over the sea hood edge.

Starboard mounting bracket with washer “spacers” in place.

The final step is to add the control lines and it depends on the length of the traveler and the purchase. For a 4:1 purchase with the #1655 kit I installed Harken provides this formula: Track Length x 4 plus 3 feet and they specify 8 MM line. So I went to my local West Marine rigging department with formula in hand and they supplied two control lines with an eye on one end and the bitter end whipped. Back at the boat I removed the hex head bolts that held down the sheave assembly on the control end, being careful not to lose the ball bearing assembly mounted in the sheaves when I lifted it, and looped the eye of the control line over the “deadend horn”. Then I re-tightened the sheave assembly back into the control end.

Harken provided a clear guide on how to reeve the control lines though the sheave and then finally though the cam cleat to get a 4:1 purchase. Unfortunately for me, I won’t be able to experience the benefits of the traveler upgrade because the boat was hauled out for the winter and put “on the hard” for scheduled maintenance in the spring, but I'm sure the upgrade will prove to be a great improvement.

Completed Traveler Upgrade