When you turned on your computer today, you were probably thinking, "Man, I sure hope I get something exciting to read about, like a guy writing about the condition of the through-hulls in his boat."

It's your lucky day. Here we go.

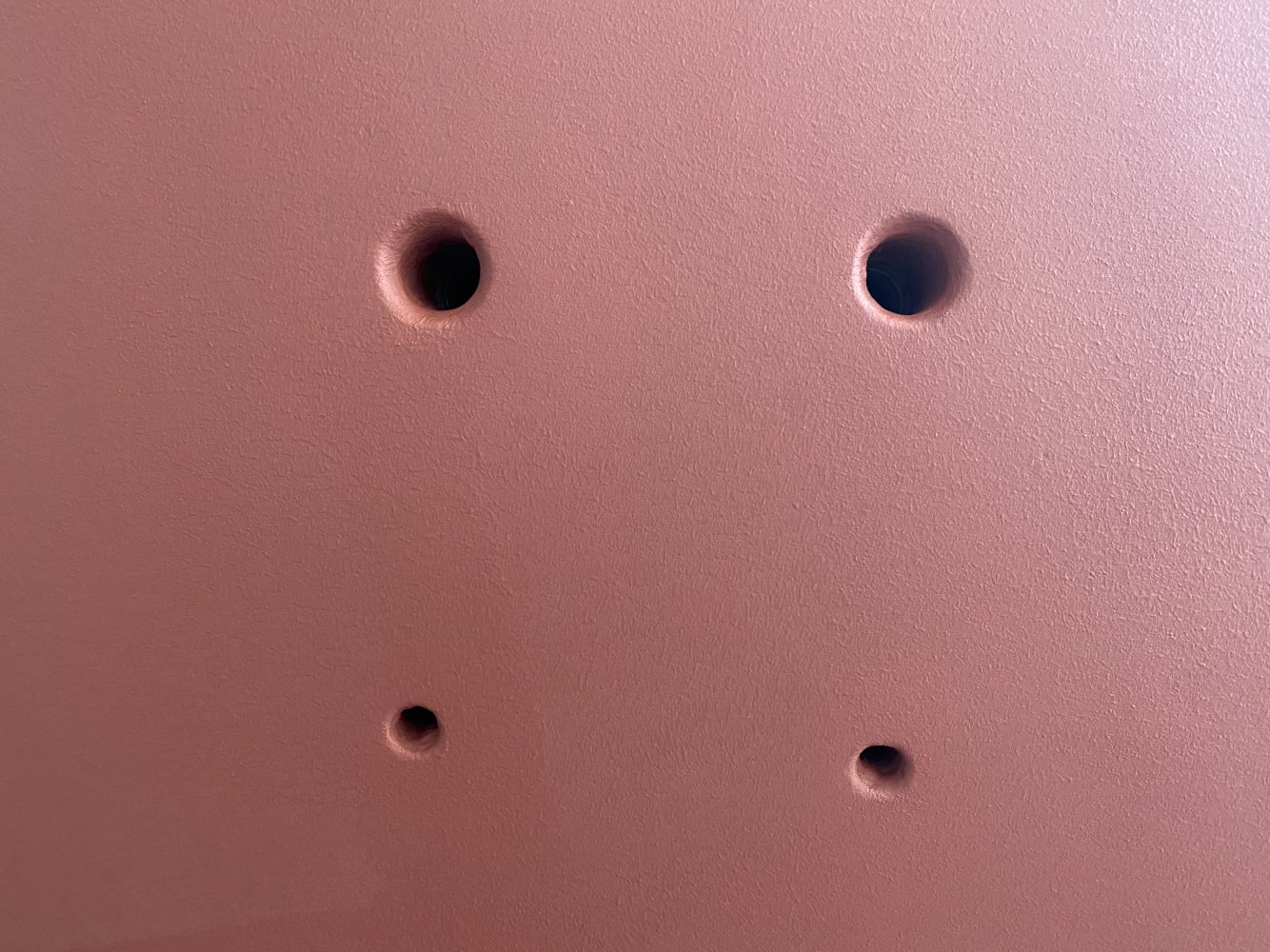

My 32-200 has four through-hulls in the head area on the starboard side of the boat.

I suspect these are all factory glassed-in installs from the 1990 launch.

Large #1: Direct blackwater out from the head

Large #2: Holding tank blackwater pump-out (via dedicated Whale Gusher pump)

Small #1: Intake for saltwater head flush

Small #2: Head sink drain.

Inboard, these are gated with Marelon valves. All are in excellent condition and work well. I think Marelon would be difficult to ever beat in this circumstance, wholly protected from UV light, and impermeable to corrosion or rust.

I also have a Y valve (not shown) to allow blackwater to go directly out of the boat or to be sent to the holding tank. It was stuck and I had been leery of unsticking it in the water, but I managed to free it so that it too is working just fine.

On the port side, I have three through-hulls under my galley sink.

1. Galley drain.

2. Saltwater intake for galley sink.

3. Raw water intake for engine impellet (with integrated grate)

All are gated on the inboard side with Marelon valves which work well.

My surveyor had noted a potential weakness with the impeller hose. I inspected the valve end and found everything in order. The end that connects to the impeller, however, was worn and cracking/rusting along the reinforcing wire in hose. I was able to clip off the last 1" of the hose and re-attach it to the impeller easily. My project manager at the boatyard suggested the best way to cut these wire-reinforced hoses was to take a sharp blade (box cutter or equivalent) and cut the rubber portion, then trim the reinforcing wire with a good pair of diagonal wire cutters. (He kept calling the cutters "dykes," and it took me a minute to pin him down about what exactly he meant.)

Above the waterline on the port side I have a through-hull which is an exit for the emergency back-up spinner bilge pump:

The inboard side is accessible via a circular door in the port bench settee:

The other end connects to the spinner pump in the bilge. This provides a nice handy upward trajectory for the centifugal pump, so there is little chance of an airlock bubble.

Finally, at the aft end above the waterline, I've got at starboard:

1. Wet exhaust

2. Cockpit scupper

3. Primary bilge

4. Shower bilge

5. [Edit August 2nd, 2020] Propane cockpit locker drain.

6. Manual bilge pump from the cockpit

At port:

1. Cockpit scupper

These all seem functional, viewed from the interior. None are valved, all have high loops to prevent backwash while under way. I still need to figure out what the "other" small tube is. I think it's from the engine (or maybe an overflow line from the hot water tank?)

I also have two through-hull points forward of my keel for my sounder and paddlewheel transducers. These too seem to be in good shape.

So there you have it. All through-hulls and valves seem to be in good shape.

I prodded all of the backing plates and none of them were soft. I think I'm in good shape until the next haul-out.

It's your lucky day. Here we go.

My 32-200 has four through-hulls in the head area on the starboard side of the boat.

I suspect these are all factory glassed-in installs from the 1990 launch.

Large #1: Direct blackwater out from the head

Large #2: Holding tank blackwater pump-out (via dedicated Whale Gusher pump)

Small #1: Intake for saltwater head flush

Small #2: Head sink drain.

Inboard, these are gated with Marelon valves. All are in excellent condition and work well. I think Marelon would be difficult to ever beat in this circumstance, wholly protected from UV light, and impermeable to corrosion or rust.

I also have a Y valve (not shown) to allow blackwater to go directly out of the boat or to be sent to the holding tank. It was stuck and I had been leery of unsticking it in the water, but I managed to free it so that it too is working just fine.

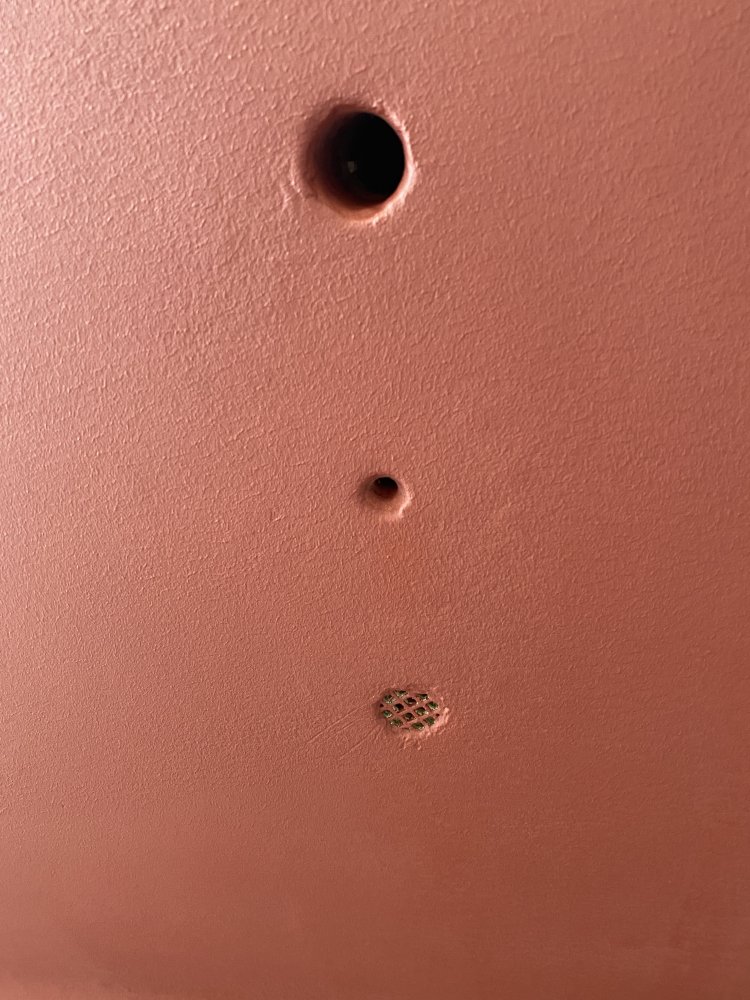

On the port side, I have three through-hulls under my galley sink.

1. Galley drain.

2. Saltwater intake for galley sink.

3. Raw water intake for engine impellet (with integrated grate)

All are gated on the inboard side with Marelon valves which work well.

My surveyor had noted a potential weakness with the impeller hose. I inspected the valve end and found everything in order. The end that connects to the impeller, however, was worn and cracking/rusting along the reinforcing wire in hose. I was able to clip off the last 1" of the hose and re-attach it to the impeller easily. My project manager at the boatyard suggested the best way to cut these wire-reinforced hoses was to take a sharp blade (box cutter or equivalent) and cut the rubber portion, then trim the reinforcing wire with a good pair of diagonal wire cutters. (He kept calling the cutters "dykes," and it took me a minute to pin him down about what exactly he meant.)

Above the waterline on the port side I have a through-hull which is an exit for the emergency back-up spinner bilge pump:

The inboard side is accessible via a circular door in the port bench settee:

The other end connects to the spinner pump in the bilge. This provides a nice handy upward trajectory for the centifugal pump, so there is little chance of an airlock bubble.

Finally, at the aft end above the waterline, I've got at starboard:

1. Wet exhaust

2. Cockpit scupper

3. Primary bilge

4. Shower bilge

5. [Edit August 2nd, 2020] Propane cockpit locker drain.

6. Manual bilge pump from the cockpit

At port:

1. Cockpit scupper

These all seem functional, viewed from the interior. None are valved, all have high loops to prevent backwash while under way. I still need to figure out what the "other" small tube is. I think it's from the engine (or maybe an overflow line from the hot water tank?)

I also have two through-hull points forward of my keel for my sounder and paddlewheel transducers. These too seem to be in good shape.

So there you have it. All through-hulls and valves seem to be in good shape.

I prodded all of the backing plates and none of them were soft. I think I'm in good shape until the next haul-out.