Fuel Bleeding Questions

I've had to bleed the fuel lines on my M-25 twice in the last month: Once after changing the engine-mounted fuel filter, and once after running it with the fuel SOV closed (I've graduated to the "those that will" camp). I'll need to bleed it again after I change the frame-mounted filter (I didn't have the part when I did the engine filter).

Question #1: Is it really necessary to bleed air from both the engine-mounted fuel filter housing and the fuel injector bleed ports. As they are only located a few inches apart, and, since the fuel injector bleed port is further downstream, it seem that bleeding air from just the FI port should suffice.

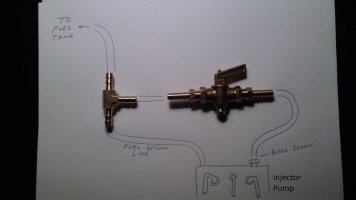

Second: Bleeding fuel lines can be messy. I caught some of the fuel in absorbent pads, but later had to clean the rest from the bilge. To minimize the mess, I stopped bleeding as soon as fuel exited from the port, even though there may have been more air trapped further up the line. Since fuel-line bleeding will be a recurring maintenance item, I had a thought: Can I replace the fuel injector bleed cap with a fuel shut-off valve and a fuel line to route the bled air and fuel back into the fuel return line (the line that carries excess, unused fuel from the injector housing back to the fuel tank)? I don't think the introduction of air into the fuel return line would cause any problems--it would wind up venting from the fuel tank.

Lastly, does anyone know the model number for Facet electrical fuel pump used in the 85 E32-3. I'm having trouble finding the model number on my unit.

Thanks,

Ken

I've had to bleed the fuel lines on my M-25 twice in the last month: Once after changing the engine-mounted fuel filter, and once after running it with the fuel SOV closed (I've graduated to the "those that will" camp). I'll need to bleed it again after I change the frame-mounted filter (I didn't have the part when I did the engine filter).

Question #1: Is it really necessary to bleed air from both the engine-mounted fuel filter housing and the fuel injector bleed ports. As they are only located a few inches apart, and, since the fuel injector bleed port is further downstream, it seem that bleeding air from just the FI port should suffice.

Second: Bleeding fuel lines can be messy. I caught some of the fuel in absorbent pads, but later had to clean the rest from the bilge. To minimize the mess, I stopped bleeding as soon as fuel exited from the port, even though there may have been more air trapped further up the line. Since fuel-line bleeding will be a recurring maintenance item, I had a thought: Can I replace the fuel injector bleed cap with a fuel shut-off valve and a fuel line to route the bled air and fuel back into the fuel return line (the line that carries excess, unused fuel from the injector housing back to the fuel tank)? I don't think the introduction of air into the fuel return line would cause any problems--it would wind up venting from the fuel tank.

Lastly, does anyone know the model number for Facet electrical fuel pump used in the 85 E32-3. I'm having trouble finding the model number on my unit.

Thanks,

Ken

Attachments

Last edited: