Dan, Since we both sail in restricted waters as far as waste dumping goes, you on the Great Lakes and I on the Chesapeake, we are in the same boat (sorry about that) as far as sanitation goes on board. First of all, I think your tank was never pumped out properly. As was stated here in this forum, when using a pump out station gear the hose going to your boat has a “sight glass” of sorts usually in the form of a clear plexiglass pipe connection next to the hose valve that will clear show the extraction of the tank waste. Also you seem to indicate that someone else did the pumping out, that is handled the hose on board. I’ve always done that chore as most sailors on the bay do and by using the “sight glass” you should know if anything is being pumped out and see when the flow stops indicating that the tank is empty. So, I suggest the first step is for you to make another trip to a pump out station, handle the hose yourself and look at the sight glass/pipe to make sure you tank is empty. Then, if you can, make a visual inspection of the tank by banging on it or even trying to move it around to “feel” if it full. This might require you to loosen up any restraints holding the tank down. If it’s still full after your next pump out attempt (and nothing was seen thru the sight glass during the whole process) then the hose to the deck fitting is clogged but I find that highly unlikely since it would take a lot to clog it up. I suspect that the tank wasn’t properly pumped out in the first place. As for the vent hose. You say that that was waste discharging from the vent. Was this all the time? Perhaps there was just some water/waste in the line? After another pump out, done correctly, and checking the tank to see if it full, I’d give another look at that vent to see if it’s still discharging fluid.

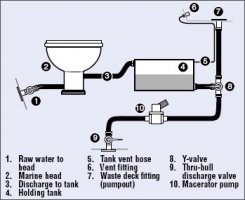

As for head plumbing, sometimes it can look like something you might find as a nuclear power plant, especially if a “Y” with overboard pumping is installed. When I bought my E32-3 the head was in terrible, smelly shape. I replaced the waste tank, added a tank monitoring system (which also monitors the fresh water tanks), replaced all the hoses and removed the “Y” valve and overboard manual pump since no overboard dumping on the bay is allowed. I capped off the overboard thru hull valve and they’re still in place in case someone wants to put a “Y” valve back in and have overboard pumping again. This greatly simplified the situation. I should also say that I think a slight whiff of waste tank, from the vent, is normal IMO. After all you’re replacing air with fluid and it’s got to go someplace and that’s one of the reasons for the vent. I will smell it sometimes when I’m under sail and someone else uses the head which is natural since I’m sort of downwind from the head. But it’s just a whiff and nothing more.

One last thing is to check your joker valve on the head itself, especially if you’re getting “drain back” from the waste line and even a smell in the head compartment. That's assuming that the waste line isn’t permeated and needs replacing. I recently replaced my old and worn out Raritan head with a new Jabsco head (which I consider better) and had “drain back” right away. After some investigation I determined that the brand new joker valve that came with the new head was defective. After I replaced the joker valve all my problems went away.

I’m assuming that you’re new to marine sanitation so please excuse me if I’ve been stating the obvious on this subject. These are all things that I’ve learned by working on my Ericson.