caveat 1: I'm not a metallurgist. However, I trained as a silversmith and had a long career designing metal consumer products (flatware, etc.) and taught industrial design shop (among other subjects) for students at the college level.

caveat 2: What follows is for ferrous and non-ferrous metals commonly used for consumer products like flatware and boats; steels, copper, brass, bronze, etc. More exotic metals like titanium, etc are generally similar, but have unique characteristics. Also, of the commonly used non-ferrous metals, aluminum is kind of it's own quirky thing and doesn't adhere to all the rules as exactly as copper, silver, etc typically do. Further complicating things is a dizzying number of metal alloys. What follows is grossly simplified.

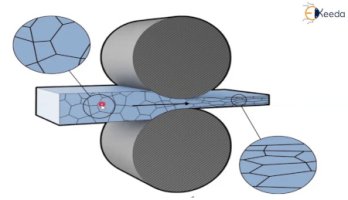

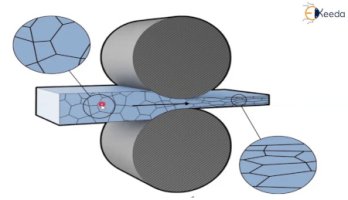

Metal, in general, does not have grain like a tree. It's basic structure is crystalline, not cellular. Metal doesn't grow toward the light and does not need to transfer water and chemicals. When it's poured from its molten state into a form it cools into crystals. Two ways of making product from those rough billets are forging and rolling. Forging can be free-form, with a hammer and anvil. Or, it can be in dies, like making a combination wrench. Rolling creates sheets of various sizes and configurations that is then manipulated in different ways. The steel for your chain-plates was undoubtedly created this way. Below is an illustration from a pretty good video, though the presenter's accent is a bit hard to sift through.

link:

Strain Hardening - Strain Hardening - Material Technology

When a hot blank is slammed between a forge die to make a wrench there is a direction to the crystalline elongation that travels out. Likewise, when rolled through a mill, there is a kind of direction created, grain if you will. Grant's observation on your part is right on. For our purposes as boat owners, I don't think this grain matters. In products like ICBMs and America's Cup boats, where optimum performance is important, that structure can be analyzed and used for the best. For our kinds of applications I think the general solution is to just over-build it.

To relax the stiffness created by compression, the metal can be heated and cooled, annealing. The cycle of that depends on the metal. And, when ordering metal stock you can often specify dead soft, half-hard, hard. Given a choice, I would

not order full-hard for something like chain-plates. I'd feel comfortable with soft or maybe half-hard. That's more an intuitive choice, rather than scientific. I could be wrong.

Tool steels are a different animal. Those alloys can be given specific strength characteristics by applying different heating and cooling cycles, hardening and tempering.

Loren's comments about polishing align with my experience. Polishing compounds are just finer abrasives, working down to smaller and smaller scratches that can ultimately only be seen on the microscopic level. The smaller the scratches, the less ingress for oxidizers. The only enhancement I'd make to what he writes is to say that rouge is generally considered the last, finest cut. Prior to that I'd start with a cut-down followed by an intermediate, then rouge. There are compounds optimized for specific metals. A good abrasive supplier will be able recommend the best, or you can buy kits. Use separate wheels for each compound and clean the piece well in between each 'grit'. Otherwise you'll contaminate the finer compounds with the coarser. Don't go too crazy though. It's a rabbit hole.

(I'm sorry if I got too pedantic. It's hard to turn off 'teacher' mode. I welcome correction from people who have a knowledge base greater than my college sophomore level.)

Cheers,

Jeff