Hello. My wife and I own a 1975 Ericson 27, and this will be our third season with it. I am puzzled by a crack that occurred recently in the keel structure of the boat, which is sitting on a cradle in outdoor winter storage here in Chicago. I saw the crack on a visit to the boatyard after the latest spell of single-digit temps.

The keel sump had frozen solid, despite my emptying and filling it about halfway with RV/marine antifreeze before winter (Splash -50 degree burst protection). I assume some water got in and diluted the antifreeze enough for it to freeze like an ice cube. I’m not sure, though, if the frozen sump compartment is the culprit for the crack.

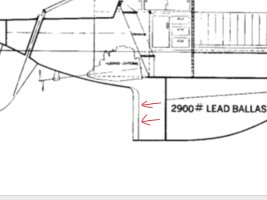

After thawing the ice with my heat gun and emptying the sump, I could not find a crack on the inside of the sump wall. We found by tapping the inside of the sump compartment that its location is not behind the crack. The bottom of the sump is 5 inches higher and 4 inches in front of, or to the fore of, the crack (see photo). I don’t know if the possible expansion of the sump compartment from ice formation would cause a crack below and to the rear of the sump. I suppose the pressure could cause cracking in a thinner portion of the keel downstream.

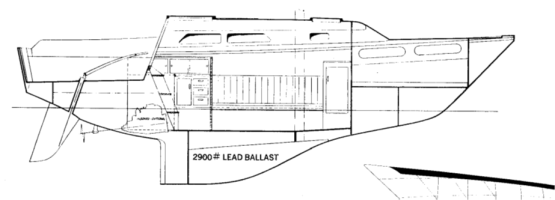

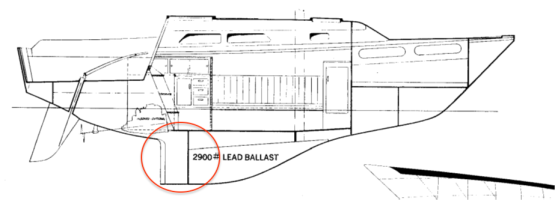

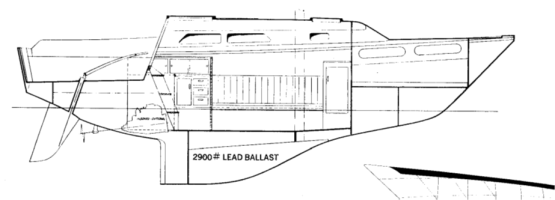

I am also wondering if there is a compartment or empty space to the rear of the sump that could collect water? I don’t see it in the diagram below. I also haven’t found yet how to reach the crack from the inside to repair the inside surface.

Finally, another question I have is if the resting of the rear section of the keel directly on a steel center support of the cradle could cause a crack? The forward part of the keel is resting on a small piece of plywood on the center support, but the rear of the keel is resting directly on the steel support. I wonder if the crack was caused by the lack of a wooden cushion between the rear part of the keel and the cradle? Your comments on this problem will be appreciated.

The keel sump had frozen solid, despite my emptying and filling it about halfway with RV/marine antifreeze before winter (Splash -50 degree burst protection). I assume some water got in and diluted the antifreeze enough for it to freeze like an ice cube. I’m not sure, though, if the frozen sump compartment is the culprit for the crack.

After thawing the ice with my heat gun and emptying the sump, I could not find a crack on the inside of the sump wall. We found by tapping the inside of the sump compartment that its location is not behind the crack. The bottom of the sump is 5 inches higher and 4 inches in front of, or to the fore of, the crack (see photo). I don’t know if the possible expansion of the sump compartment from ice formation would cause a crack below and to the rear of the sump. I suppose the pressure could cause cracking in a thinner portion of the keel downstream.

I am also wondering if there is a compartment or empty space to the rear of the sump that could collect water? I don’t see it in the diagram below. I also haven’t found yet how to reach the crack from the inside to repair the inside surface.

Finally, another question I have is if the resting of the rear section of the keel directly on a steel center support of the cradle could cause a crack? The forward part of the keel is resting on a small piece of plywood on the center support, but the rear of the keel is resting directly on the steel support. I wonder if the crack was caused by the lack of a wooden cushion between the rear part of the keel and the cradle? Your comments on this problem will be appreciated.