Another project completed, hopefully permanently.....

Ever since upgrading the charging system on my E38 it was eating belts. The alternator is 125 amp cold and 107 amp hot rated. The progression went like this:

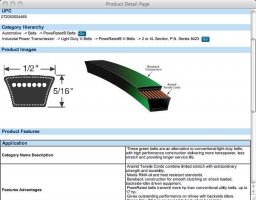

-Install upgraded alternator and use 3/8" belt. Not good, belt bottoms in new alternators 1/2" belt pulley. Kills belt pretty quickly, as expected.

-Install 1/2" belt, Gates "green stripe" variety. Sits quite high in the engine crankshaft and waterpump pulleys. It eats this too. Also likes to eat Dayco belts or anything else I can feed it.

-Regulator dies and new Balmar ARS5 can power limit the alternator so it is adjusted down to keep belts alive a bit longer but they still live on "death row"

-New waterpump pulley is fabricated by local shop and stock crankshaft pulley is modified with a wider, deeper 1/2" groove. It still eats belts.

The belts are turning to dust. Every hour of operation means the belt needs adjustment. Black dust tells the tale, everywhere. The alignment of all pulleys is checked and rechecked throughout this. They are always in perfect alignment. Checked with straightedge, etc. Once the alternator powers up the belt starts jumping and vibrating under load. I searched for a long time until I found a machinist in New Mexico, of all places that was capable of making custom 6 groove serpentine belt pulleys. Why a serpentine type belt? Well, by my estimates measuring the surface area of the serpentine belt has 100%-150% more surface area than a 1/2" belt. The other reason is that when perusing the engines at the boat shows, most if not ALL new engines have serpentine style belts. There has to be a reason for this. Be it increased surface area, reduced friction, reliability, etc. Maybe I shouldn't be refering to these belts as "serpentine" as they aren't always used in a serpentine configuration, they are really flat 6 groove belts, but thats semantics I suppose.

The new pulleys are installed and the engine has been test run at various RPM's. The serpentine belt is much more stable, doesn't jump around much at all at any RPM. I am optimistic that this will solve the belt wear issues, permanently. If not I do have one more option and that is to add an idler pulley that will cause a 270 degree belt engagement of the alternator pulley. Hopefully it doesn't come to that.

Once I get the approval of the machinist I will post his contact info. His work is extremely nice, bolted right on with no alignment issues. I would highly recommend him for custom pulleys, serpentine, V-belt or anything else.

The first shot is the pulleys, the second is the old 1/2" belt setup and the third the new serpentine.

Enjoy, RT

Ever since upgrading the charging system on my E38 it was eating belts. The alternator is 125 amp cold and 107 amp hot rated. The progression went like this:

-Install upgraded alternator and use 3/8" belt. Not good, belt bottoms in new alternators 1/2" belt pulley. Kills belt pretty quickly, as expected.

-Install 1/2" belt, Gates "green stripe" variety. Sits quite high in the engine crankshaft and waterpump pulleys. It eats this too. Also likes to eat Dayco belts or anything else I can feed it.

-Regulator dies and new Balmar ARS5 can power limit the alternator so it is adjusted down to keep belts alive a bit longer but they still live on "death row"

-New waterpump pulley is fabricated by local shop and stock crankshaft pulley is modified with a wider, deeper 1/2" groove. It still eats belts.

The belts are turning to dust. Every hour of operation means the belt needs adjustment. Black dust tells the tale, everywhere. The alignment of all pulleys is checked and rechecked throughout this. They are always in perfect alignment. Checked with straightedge, etc. Once the alternator powers up the belt starts jumping and vibrating under load. I searched for a long time until I found a machinist in New Mexico, of all places that was capable of making custom 6 groove serpentine belt pulleys. Why a serpentine type belt? Well, by my estimates measuring the surface area of the serpentine belt has 100%-150% more surface area than a 1/2" belt. The other reason is that when perusing the engines at the boat shows, most if not ALL new engines have serpentine style belts. There has to be a reason for this. Be it increased surface area, reduced friction, reliability, etc. Maybe I shouldn't be refering to these belts as "serpentine" as they aren't always used in a serpentine configuration, they are really flat 6 groove belts, but thats semantics I suppose.

The new pulleys are installed and the engine has been test run at various RPM's. The serpentine belt is much more stable, doesn't jump around much at all at any RPM. I am optimistic that this will solve the belt wear issues, permanently. If not I do have one more option and that is to add an idler pulley that will cause a 270 degree belt engagement of the alternator pulley. Hopefully it doesn't come to that.

Once I get the approval of the machinist I will post his contact info. His work is extremely nice, bolted right on with no alignment issues. I would highly recommend him for custom pulleys, serpentine, V-belt or anything else.

The first shot is the pulleys, the second is the old 1/2" belt setup and the third the new serpentine.

Enjoy, RT