My solution to Fuel Tank access ports

While I agree that the KISS option of no access ports is ideal, if you want or need to get access to your fuel tank compartments you are going to need access ports.

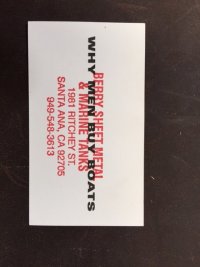

I ran through this scenario just after I bought my boat with a full fuel tank (50 gal) of unknown age and condition. From the engine hours logged, the fuel could have been twenty years old. I read the threads on this site and saw the Seabuilt access covers. My tank is a 1990 Berry Sheetmetal replacement of the 1981 original, built in 18 gauge stainless steel. The fuel tank on the E36RH is under the starboard settee and the top is fully accessible. I really wanted to see inside my four section tank BEFORE I started the engine but I could not justify the cost of the available access port options. I could see some tar deposits in the tank through the fuel sender's 1.5 inch hole but the fuel looked clear and there was no evidence of water. The engine started fine and I ran down the fuel over the next four years with no issues. Last year I sheared the vent fitting off the side of the boat and ingested a bunch of water into the tank over the winter. I had the FULL tank pumped out, for $360, after I had just filled it!

The fuel was so bad they did not recommend filtering it. After pumping out through the fuel sender hole, there was still ~ 1/2 inch of gunky fuel left in the bottom of the tank. Now I really needed to get into the four compartments to see and clean.

During the previous years I had figured out a way to install the access ports for much less cost than the previous options. My fuel sender is mounted via 5 tapped ss screws and has a Buna-N gasket to seal it to the tank top. It does not leak. Access ports just need enough clamping pressure to seal the gasket. Why wouldn't a single plate on top of a Buna-N sheet gasket held by ss screws tapped into the tank top work? This avoids the plate or backer inside the tank and the nut and bolt to clamp it, plus the hassle of holding the inside fastener during tightening. The #10-32 x 1/2 ss screws are a lot less expensive than larger nuts/bolts/washers. I decided on square 6 x 6 inch access holes with 8 x 8 inch, 0.060 inch thick 304 stainless plates, pre-cut from McMaster Carr, so I would not have cutting of the covers to deal with. I got 3/32 inch thick 12" x 24" Buna-N rubber sheet to use as gaskets and cut it with scissors to 8 x 8. I got a 3/16 hole punch to make the screw holes in the rubber. The total cost for 7 access plates was $125. I got 3 for my stainless water tank.

I cut the tank with my jig saw and 22 tooth metal blades (3 for 7 holes). I needed to drill a few starter holes big enough for the blade. The 88 5/32 inch screw holes required 3 bits. Tapping for the 10-32 screws was easy. The hardest parts were drilling the holes through the thicker cover plates with my little drill press and using a file to enlarge those holes slightly so that all the screws, 16 on each fuel tank cover and 8 on each water tank cover, would align and thread into the tank top. I couldn't drill accurately on the tank tops with my hand drill and the bit would walk off location slightly.

I just finished the water tank this spring. I have sailed with the covers on the fuel tank. The plate gaskets do not leak but I have found that some of the screws weep a very little fuel through the threads. My tank is 18 gauge stainless and there are only 1.5 threads in the tank top. I just bought some small O-rings to seal the screw heads and I am confident they will work. If not, I will add pipe thread sealer.

I was able to do all this work with the tanks empty except for the initial 6 x 6 cuts of the fuel tank top. I cleaned up the left over fuel in each compartment and then cleaned all the tar off the inside tank surface with mineral spirits. It came off easily and cleaned up nice. The deposits were not loose and were not going to come off and go into the filter or bother the engine. I vacuumed up all the metal chips after the cutting, drilling and tapping.

Overall, this job was well worth the effort and cost. I would take the same approach if I had a thicker aluminum tank, except use aluminum covers and TeffGel or Thread Sealer for all the stainless screws. My 0.060 cover plates are thicker and stiffer than the tank top. You could use aluminum plates the same thickness as your tank because it is so much stiffer than stainless. I think the additional threads through the thicker aluminum tank top would also eliminate the fuel weeping issue. I would wait to order the O-rings and test sail first. Let me know if you have any questions.

Mark