SurfingGuru

Junior Member

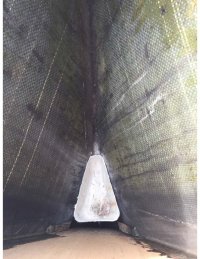

Hello All, I'm the new owner of an E32-3 out here in sunny Honolulu. I have been restoring this boat since I purchased it last summer. A few months ago I replaced the chainplate due to a fracture in the original one. In doing the repair the anchor locker was removed and reinstalled. Fast forward to yesterday, I was motor-sailing 4 hours to get the boat pulled onto the hard to complete a number of outstanding maintenance issues below the waterline. About one hour into the transit we noticed the bilge filling with water. We made it to the dry dock just fine. We couldn't find the source of the incoming water. Thinking back I remember them reinstalling the anchor locker and don't remember them messing around with the hose. I'm wondering if the drain tube was never reattached? Does anyone have any advice as to how to reinstall the tube? Seems like a passthrough at the drain location is just asking for problems. HAs anyone considered adding a bilge pump dedicated to the anchor locker?