adam

Member III

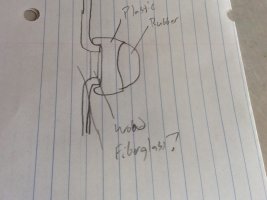

My hull deck joint seems to be leaking a bit, and when I pulled it apart I was surprised to find something completely different than the manual.

My previous boat had about a 3/4" outward flange where the deck and hull were put together.

This E35-2 has almost no outward flange (7/32") and a 1" wide strip of wood between the two flanges.

I am considering dumping the rub rail completely and either grinding away the exterior or replacing the wood with some nicely varnished wood.

BUT, does anyone know how this boat is built?

Is it possible that this boat is completely different than the manual, the deck overlaps the hull in this boat, and the ~50 little machine screws that I removed are what holds the boat together?

My previous boat had about a 3/4" outward flange where the deck and hull were put together.

This E35-2 has almost no outward flange (7/32") and a 1" wide strip of wood between the two flanges.

I am considering dumping the rub rail completely and either grinding away the exterior or replacing the wood with some nicely varnished wood.

BUT, does anyone know how this boat is built?

Is it possible that this boat is completely different than the manual, the deck overlaps the hull in this boat, and the ~50 little machine screws that I removed are what holds the boat together?